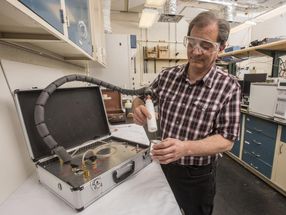

Using bacteria to make electrodes

Scientists in France have produced hematite using a bacterial pathway for use as an electrode material in Li-ion technologies.

Currently, most commercial electrode materials for Li-ion technologies are prepared using the ceramic method, which requires long heating periods at high temperatures (over 400 oC).

The research team, from across France, investigated an alternative preparation method, based on bacterial synthesis. They used a bacterium to produce an iron oxyhydroxide, lepidocrocite (γ-FeOOH), which is synthesised within the bacterium membrane. The lepidocrocite-made wall is then transformed into hematite by heating at 700 oC for one hour. This process eliminates the bacteria to leave a hematite powder compose of multiple, hollow, micro-sized, rod-like shells that have retained the shape and characteristics of the bacteria’s periplasms, which the researchers describe as ‘bacteriomorphs.’

Hematite is very good at storing electric charge (1000mA/g), making it a good material for electrodes. The researchers compared the conductivity of the hematite bacteriomorphs with un-textured hematite (crushed to destroy the bacteriomorph structure) and abiotic hematite (synthesised in the standard way, not using bacteria) and found that, after ten charge-discharge cycles at a slow speed, 91% of the initial charge storage capability was retained. This was considerably better than the other hematites, which retained only 18% (abiotic) and 8% (un-textured) of their initial charge storage capability. The researchers hypothesise that the improved performance of the bacteriomorphs is explained by their unique structure, which confers better mechanical stability to the electrode, and better contact with the electrolyte due to their porosity.

Original publication

Organizations

Other news from the department science

Get the life science industry in your inbox

From now on, don't miss a thing: Our newsletter for biotechnology, pharma and life sciences brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.