INEOS Bio wins grant for Europe's first Advanced bioethanol from waste plant.

INEOS Bio awarded £7.3m grant from One North East and the Department for Energy and Climate Change for construction of Europe’s first advanced bioethanol from waste plant using the INEOS BioEnergy Process Technology

INEOS Bio announced that it has received an offer of a £7.3m grant towards £52m construction costs for the first commercial plant in Europe using its advanced BioEnergy Process Technology. The plant, to be located at the INEOS Seal Sands site in the Tees Valley, is designed to produce 24,000 tonnes per year (30 million litres) of carbon-neutral road transport fuel and generate more than 3MW of clean electricity for export from over 100,000 tonnes per year of biodegradable household and commercial waste. This would provide the biofuel requirement of around 250,000 vehicles per year running on E10 and the electricity needs of 6000 households.

Speaking about the announcement, Peter Williams, CEO of INEOS Bio, said: “Using our technology, the waste that is collected from homes and offices and otherwise thrown away, can be re-cycled into clean biofuel for cars and renewable electricity for homes and industry.”

“This grant from One North East and the Department for Energy and Climate Change, together with the considerable support that we are receiving from organisations such as the National Non Food Crop Centre, is enabling us to make progress with our commercialisation plans in the North East of England.”

Subject to final agreements, this advanced bioethanol plant is due to be completed by 2012, creating around 40 new permanent jobs at the plant and 350 jobs in the construction phase. Once operational, it is intended that the facility will be expanded into a larger integrated biorefinery, combining advanced bioenergy production with advanced waste treatment by 2015. The biorefinery would help to meet the UK’s renewable energy targets for transport fuel, power and heat set for 2020 through the Renewable Energy Directive.

Following the successful completion of a detailed feasibility study by INEOS Bio DECC has now approved funding of £4.5m for this next phase of the project. In addition, the Regional Development Agency One North East is investing £2.8m, of which £1.8m has been secured through the Tees Valley Industrial Programme.

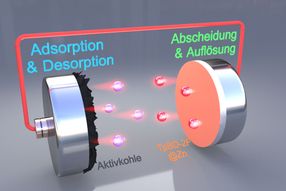

The INEOS BioEnergy Process Technology combines thermochemical and biochemical technologies to achieve energy-efficient and low-cost biofuel production from a wide range of biomass materials, including household and industrial waste. At the heart of the INEOS Bio technology is an anaerobic fermentation step, through which naturally occurring bacteria convert gases derived directly from biomass into bioethanol. This bioethanol production is integrated with combined heat and power generation. The process supports high recycling and high landfill diversion rates and an independent life cycle assessment indicates that the bioethanol produced would deliver 100% green house gas savings compared to using petrol in today’s cars.

Most read news

Topics

Organizations

Other news from the department business & finance

Get the life science industry in your inbox

From now on, don't miss a thing: Our newsletter for biotechnology, pharma and life sciences brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.