Experts identify biological control to contain fungus killer in Kenya's maize supply

Scientists offer a natural, safe and cost-effective solution to prevent future contamination of maize by the killer aflatoxin to secure the food and income of millions of small-scale farmers in Kenya and the rest of Africa

Advertisement

As Kenya once again grapples with high levels of aflatoxin contamination, which has rendered at least 2.3 million bags of maize unfit for human and livestock consumption, international experts announced that they have identified a local non-toxic form of the fungus responsible for aflatoxin that can be used to control contamination through a novel biological control approach, which is entirely safe and effective.

The experts are seeking to form a public-private partnership in Kenya through which the new approach could be widely applied, reducing a major health hazard for the public and preventing huge economic losses for farmers and the government.

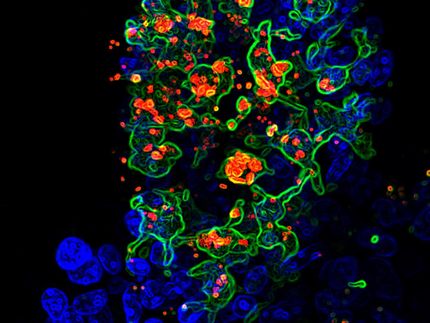

The contamination of the country's main staple with aflatoxin, a highly poisonous cancer-causing chemical produced by a fungus scientifically known as Aspergillus flavus , was a result of poor drying and storage of the grain following heavy rainfall near harvest time.

" A. flavus strains are either toxigenic (produce aflatoxin) or atoxigenic (do not produce aflatoxin). Our biocontrol technology makes use of carefully selected atoxigenic strains or the 'good guys' that can safely outcompete and virtually eliminate their toxic relative or 'the bad guys', effectively reducing contamination of the maize grains in fields," said Dr Ranajit Bandyopadhyay, a plant pathologist with the Africa-based International Institute of Tropical Agriculture (IITA),

Dr Peter Cotty of the Agriculture Research Service of the United States Department of Agriculture (USDA-ARS) and Dr Bandyopadhyay have identified biocompetitive strains of the good fungus native to Kenya that can now be used to control aflatoxin contamination in the country.

According to Dr Bandyopadhyay, a single application of this biopesticide 2-3 weeks before maize flowering is sufficient to prevent aflatoxin contamination throughout and beyond a cropping season and even when the grains are in storage.

He says that the technology's ability to continue working even when the grain is in storage ensures the safety of maize from aflatoxin contamination. "These atoxigenic strains are also carried in the grains from the field to the stores. So, even if the grains are not stored properly or get wet during or after harvest, as is happening this year, they continue to prevent aflatoxin contamination during the postharvest period," said Dr Bandyopadhyay.