Bioreactor Allows Automated Long-Term Culturing of Stem Cells

Advertisement

Human induced pluripotent stem cells (hiPSCs) are considered as a promising tool in medicine, with the potential to unlock treatments for many health conditions such as neurodegenerative diseases and disorders. However, producing large amounts of hiPSCs remains a challenge. Researchers from the Fraunhofer Translational Center for Regenerative Therapies TLC-RT at the Fraunhofer Institute for Silicate Research ISC have now developed a bioreactor that can be used for automated long-term culturing of hiPSCs.

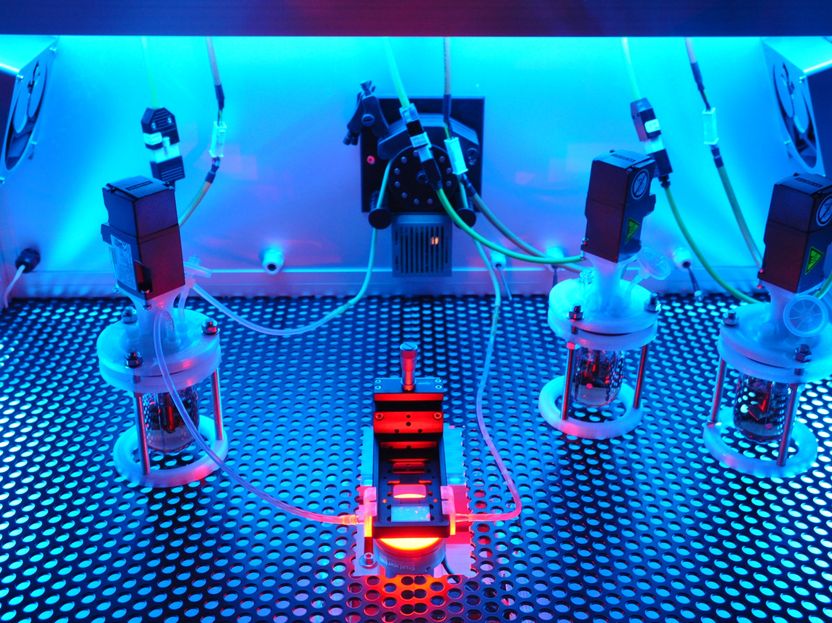

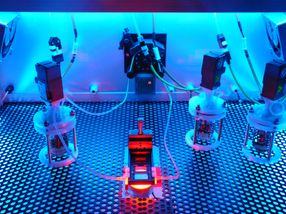

A fluid loop transports all of the liquids used to the bioreactors and the centrally positioned microscope.

© Fraunhofer ISC

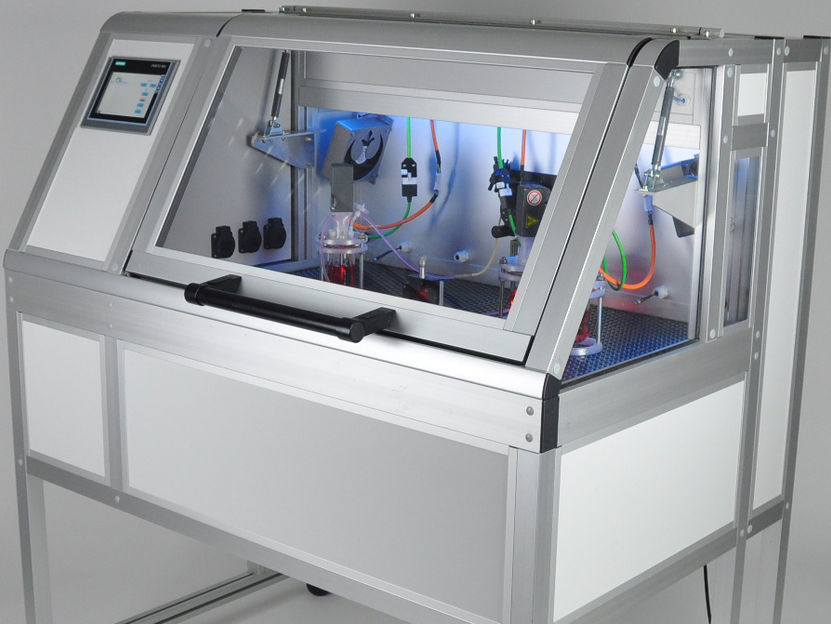

The modular incubator system with built-in bioreactors can be expanded to include additional functions.

© Fraunhofer ISC

Human induced pluripotent stem cells (hiPSCs) hold great potential for the development of cell therapies and drugs and for disease research. HiPSCs are very similar to embryonic stem cells, but they are cultured and reprogrammed in a lab from adult cells taken from the connective tissue of adult subjects. The advantage is that pluripotent stem cells have the potential to produce almost any type of cell or tissue that the body requires for self-repair purposes. It is also possible to perform patient-specific tests of potential active ingredients directly on the cells affected by a certain health condition.

To meet the rising demand for hiPSCs and allow for standardized production in larger volumes, a team of researchers from Fraunhofer ISC in Würzburg has developed a dynamic incubator and suspension bioreactor that can be used for long-term culturing of hiPSCs as part of their work on the SUSI (short for “Suspension Incubator”) project. It offers optimum conditions, such as a temperature of 37 degrees Celsius and an atmosphere saturated with five percent CO2, both of which are necessary to culture the cells. One key component of the bioreactor is the impeller, a type of stirrer that performs the important tasks of mixing, aeration and heat and mass transfer inside the glass vessel to create homogeneous conditions within the cell suspension, thereby enabling robust and reproducible cell propagation. “We focus on the good of the cells and designed and built all of the components of our bioreactor with that in mind,” says Thomas Schwarz, a scientist at Fraunhofer TLC-RT. For example, one crucial factor is the shear forces that affect the cells during the process of stirring, or agitating, the culture. The researchers used software simulations to calculate the optimal parameters for the impeller’s design, along with the most effective process parameters. Sensors inside the bioreactor monitor these parameters continuously in real time, ensuring homogeneity in the cell suspension culture, even with large quantities of cells. The glass vessel enclosing the impeller is also scalable in line with this design.

Cells cultured for three months

Four valves are linked together to create a fluid loop that transports all of the liquid solutions needed for these processes, such as the culture medium, in a sterile environment. This makes it possible to fully automate the propagation of hiPSCs, minimizing the influence of human interactions. Beyond that, the incubator also includes a microscope that was specially developed with a partner. It can be used to automatically monitor the condition of the culture medium and cell suspension to check for undesired agglomeration, which occurs when cells cluster together. As another feature, artificial intelligence (AI) is used to count the cells. During the culturing process, a neural network analyzes the geometry of the cells. “Our modular system can be expanded to include additional functions and is distinguished by its flexibility and high degree of automation, plus it allows for controlled cell handling. The closed-loop structure and automatic exchange of fluid components prevent contamination,” Schwarz explains. Various types of bioreactors can be incorporated into the Fraunhofer TLC-RT incubator, and the equipment can be adjusted individually, an option not typically offered by conventional incubators.

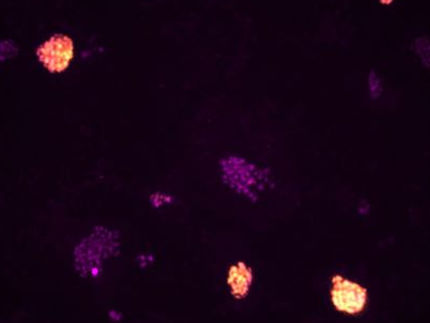

The researchers have succeeded in using the prototype bioreactor to culture cells for a period of three months without reducing their differentiation potential. They were able to adjust the system so that various types of cell differentiation based on the cultures are possible — a step forward in hiPSC technology.

Original publication

Ivo Schwedhelm, Daniela Zdzieblo, Antje Appelt-Menzel, Constantin Berger, Tobias Schmitz, Bernhard Schuldt, Andre Franke, Franz-Josef Müller, Ole Pless, Thomas Schwarz, Philipp Wiedemann, Heike Walles, Jan Hansmann; "Automated real-time monitoring of human pluripotent stem cell aggregation in stirred tank reactors"; Scientific Reports, Volume 9, 2019-8-23