More flexibility in bioprocesses

How variable biotechnology processes benefit from digital mass flow controllers

The development pipelines of biotherapeutic products are becoming increasingly diverse. Adaptability, flexibility and agility are therefore necessary to manufacture multiple products. Bioprocess plant manufacturers must keep pace with these industry demands. This also affects components and instruments in the plants. Productivity and efficiency of bioreactors depend on effective measurement and control of process variables. This involves the use of a wide range of sensors and control devices. In many cases, a properly configured single-use bioreactor platform can be flexibly adapted to many processes. Then the process can be changed to adapt the single-use bioreactor to the new target. But the devices and sensors that control these processes must be equally adaptable. In this paper, we introduce mass flow controllers with a design and performance that makes bioprocessing equipment more flexible. We illustrate how a device's capabilities and supporting documentation increase the necessary flexibility.

Download white paper now

More flexibility in bioprocesses

How variable biotechnology processes benefit from digital mass flow controllers

White Paper classification

White papers on related topics

Products on related topics

Manufacturers of similar products

See the theme worlds for related content

Topic world biopharmaceutical manufacturing

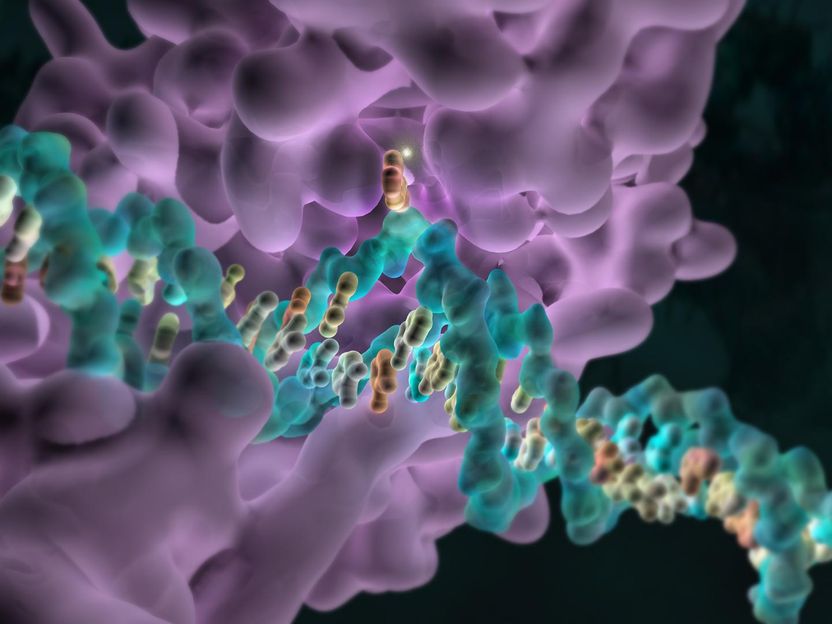

Biopharmaceutical production plays a crucial role in the development and manufacture of biologics, which are essential for the treatment of various serious diseases. Various key technologies and processes of the modern biopharmaceutical industry are used, such as cell cultures, fermentation processes and the purification of biological substances, which are necessary for the production of vaccines, monoclonal antibodies and other biological drugs.

Topic world biopharmaceutical manufacturing

Biopharmaceutical production plays a crucial role in the development and manufacture of biologics, which are essential for the treatment of various serious diseases. Various key technologies and processes of the modern biopharmaceutical industry are used, such as cell cultures, fermentation processes and the purification of biological substances, which are necessary for the production of vaccines, monoclonal antibodies and other biological drugs.