Wageningen scientists develop plants that sustainably produce 'platform chemicals'

Plant Research International and the microbiology science group, both part of Wageningen UR, have jointly developed potato plants that are capable of producing itaconic acid. Itaconic acid is a valuable raw material for the chemical industry, for instance in the production of high-quality synthetic materials. With this discovery, Wageningen UR has contributed to the more sustainable biobased production of raw materials.

Plants are particularly suitable because they use solar energy for their growth. "We now want to investigate in which part of the plant, and in which compartment of the cells, the itaconic acid can be synthesized and accumulated best," says Ingrid van der Meer, one of the scientists involved. "We already know, for instance, that tubers are far more suitable for the process than leaves."

The chemical industry mostly uses fossil oil and gas derived products as starting material for base chemicals. The use fossil resources, however, contributes to CO2 emission and fossil materials are finite. Although it may take another 50 years for fossil oil reserves to run dry, alternative, and preferably renewable sources for production of chemical building blocks need to be developed today. With this in mind, Wageningen UR is exploring the options for using plants to produce compounds that can replace petrochemicals.

Plants form a very attractive production system to supply building block chemicals for the chemical industry. They are eminently capable of producing large quantities of one specific substance, even hundreds of thousands of tons, which is a scale that meets the requirements of the chemical sector. Additionally, by nature plants have significant 'chemical machinery' in place that can be relatively easily adapted via molecular breeding. And due to the plants' use of solar energy, plants may an eco-friendly way of producing raw building block chemicals.

In their research into chemicals production by plants, WUR scientists are mainly focussing on substances which potentially can be used in bulk volumes, but still relatively valuable, and which can act as a starting material for more than one chemical product. Such substances are also called 'platform chemicals' as they serve as the basic material for numerous chemical processes.

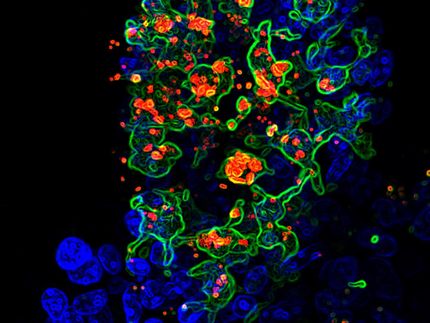

One of the substances that can be used this way is itaconic acid, a natural compound with a structure that resembles citric acid. Itaconic acid can be used to produce many different products. Itaconic acid can for example serve as a starting material for production of methacrylate, building blocks for polymethyl methacrylate acrylic plastics, with a global production volume of 3 million tonnes. In nature, itaconic acid is produced by the fungus Aspergillus terreus. A commercial strain of this fungus is already being used for the industrial production of itaconic acid, although this production method has high costs in terms of money and energy, preventing large scale use of this molecule Itaconic acid is currently used in small quantities: about 10,000 tons a year.

The first breakthrough for the Wageningen scientists was to identify the genetic code for the production of itaconic acid within the fungus. This genetic information was then introduced into potato plants via genetic modification, expanding its already extensive chemical machinery. Sure enough, the plants turned out to be capable of producing itaconic acid.

The scientists have yet to determine the ideal way to deploy this system in practice. They are still dealing with issues such as whether the accumulation rate in potato can be further optimized and how the itaconic acid can best be harvested.