Artificial Nanopores Take Analyte Pulse

Reliable nanopores by two-step etching

Advertisement

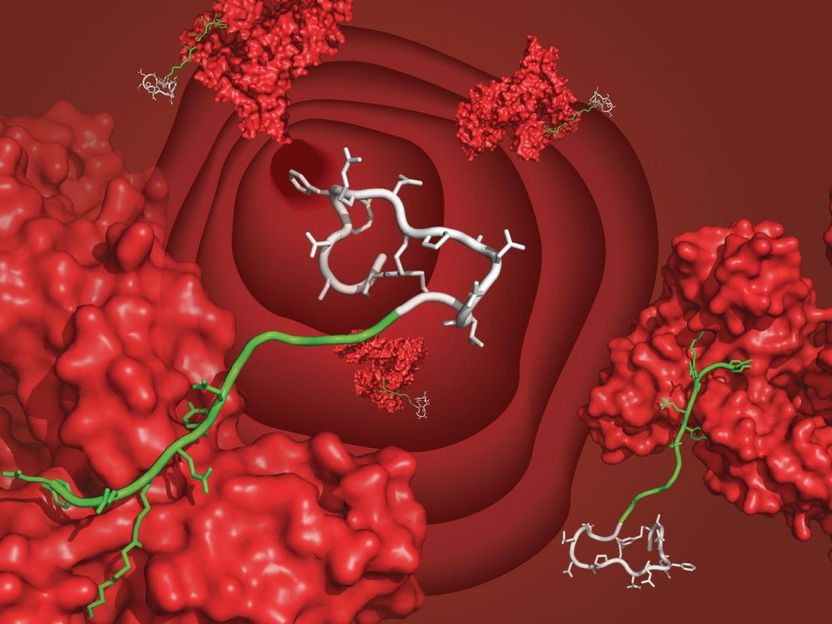

Resistive pulse sensing represents a very attractive method for identifying and quantifying biomedical species such as drugs, DNA, proteins, and viruses in solution. This method involves measuring changes in the ionic current across a membrane containing a single nanometer-sized pore that separates two electrolyte solutions. As the biological analytes make their way through the pore, they induce transient downward current pulses in the ionic current by transiently blocking the nanopore. The frequency, duration, and magnitude of the current pulse contain telltale information that AIDS the identification and quantification of the analyte. A biological nanopore, -hemolysin, supported by a lipid bilayer membrane, works well in the detection of various analytes. However, a major impediment to this system is its lack of mechanical robustness. Indeed, these biological membranes tend to rupture within a few hours, thus precluding their application in practical sensing devices. Now a team of researchers at the University of Florida have come up with a major breakthrough that will aid the reproducible fabrication of robust synthetic single-nanopore membranes.

The nanopores are prepared by a track-etching method. In this approach, a high-energy particle is passed through a synthetic polymer membrane to create a damage track, which is then chemically etched to convert the track to a pore. A major challenge has been ensuring control and reproducibility of the diameter of the resulting pore. Charles R. Martin and his colleagues have developed a two-step etching method to reproducibly fabricate conical pores in polymer membranes with predictive control of the diameters of the pore openings. The conical pores have two openings on opposite faces: a large-diameter base and a small-diameter tip. Much of the sensing action occurs at the tip, since the bioanalytes block the tip while moving across the membrane. It is thus imperative to control the size of this tip opening.

The researchers use the first etch step to define the base and the tip of the conical pores in the membrane. Subsequently, they use a second etching step, while continuously monitoring the ion current, and stop the etching process when the ion current across the membrane reaches a certain value, corresponding to a well-defined tip diameter. This method allows the predictive and reliable fabrication of conical pores with tip openings varying from 10 to 60 nm, which is in the right regime for detecting biological analytes. Martin and his colleagues have illustrated the dramatic potential of these membranes by detecting a protein analyte, bovine serum albumin, using nanopore sensors with two different tip diameters. The protein more effectively blocks the pores of a nanopore sensor with a tip diameter of 17 nm as compared to a sensor with 27-nm tips, and this is reflected in the current pulse data. "This method may allow us to take artificial nanopore sensors from the bench top to the practical prototype-device development stage", said Martin, emphasizing that the reproducible preparation of artificial nanopores is critical for the development of resistive-pulse sensors.

Original publication: Author: Charles R. Martin et al.; "A Method for Reproducibly Preparing Synthetic"; Small 2007.