Simple, mass production of giant vesicles using a porous silicone material

A technique to generate large amounts of giant vesicle (liposome) dispersion has been developed. The technique involves adsorbing a lipid into a silicone porous material resembling a "marshmallow-like gel" and then squeezing it out like a sponge by impregnating a buffer solution.

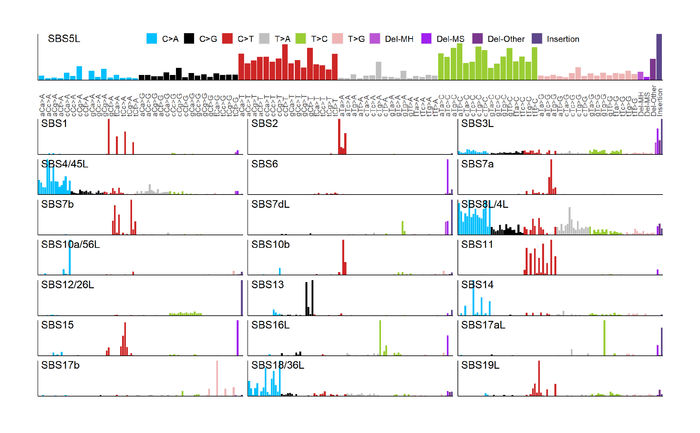

Marshmallow gel: macroscopic and microscopic image (Scanning Electron Microscopy).

Gen Hayase

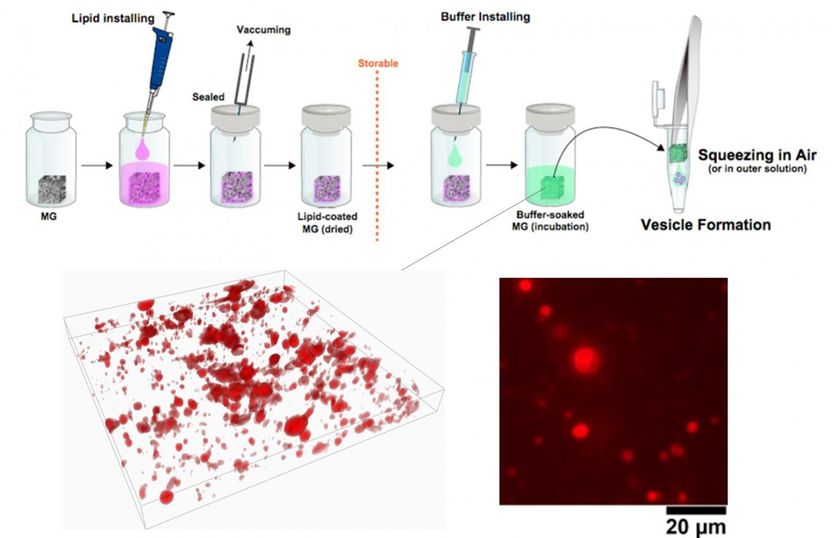

Upper: Schematic image of this method - giant vesicles are squeezed out from marshmallow gel. Lower left: GV in the MG just before the squeezing (3D image); right: GVs squeezed out from the MG.

Gen Hayase

This work was conducted by Dr. Gen Hayase (Assistant Professor) from the Tohoku University Frontier Research Institute for Interdisciplinary Sciences, and Dr. Shinichiro Nomura (Associate Professor) from the Graduate School of Engineering Robotics, Department of Robotics at Tohoku University. This simple method is expected to be applied not only as a tool for cell research requiring giant vesicles but also for medical and cosmetic purposes.

Giant vesicle (GV), a liposome consisting of a phospholipid membrane, has a structure similar to live cells and is several micrometers in size. For this reason, it has been used for various biochemical experiments such as the introduction of functional molecules into living cells, and also made into a vessel of artificial cells and molecular robotic research.

Many methods have been proposed for the preparation of GV dispersions, but in the lab, the method of producing large quantities of several hundred milliliters at one time has been limited. In 2011, Nomura discovered that GVs were generated by adsorbing lipid into porous polydimethylsiloxane (PDMS) and squeezing it in a buffer solution.

The practical development of the GV generation method and improvement of its efficiency is achieved by using a pore-controlled silicone composition flexible macroporous material, which can be described as a "marshmallow-like gel" given its consistency.

The microstructure of MG is composed of a skeleton with a diameter of several micrometers and a pore size of several tens of micrometers, and the fine skeleton surface has a smooth hydrophobic quality. When MG absorbs chloroform containing phospholipids and vacuum drying is done, phospholipids are thought to orient the hydrophobic group toward the pore side of the MG skeleton/hydrophilic group.

If buffer solution is impregnated here, GV is formed in the pores immediately. The GV dispersion can be removed by squeezing out this MG with a buffer solution. "We also found that the hydrophilic molecular group can be included in GV with high efficiency by just adding molecules to the buffer in advance" said Dr. Hayase.

As a demonstration, a marshmallow-like gel with lipid impregnated was packed into a commercially available "coffee pot" and pressed; GV dispersion was produced. Since it is possible to generate GV even with such a simple procedure, it is expected that the method will be useful as a way of GV generation.

The MG is relatively easy to produce, and it is possible to generate vesicles many times with the same sample. This method might be useful as both an artificial cell research tool and also have applications for medical and cosmetic products that can be generated on the spot, such as DIY. The research team is now developing a simpler MG fabrication method, which will be announced in a year.