Cleanroom on demand

“Clean Multipurpose Cover” is the world’s first flexible cleanroom system

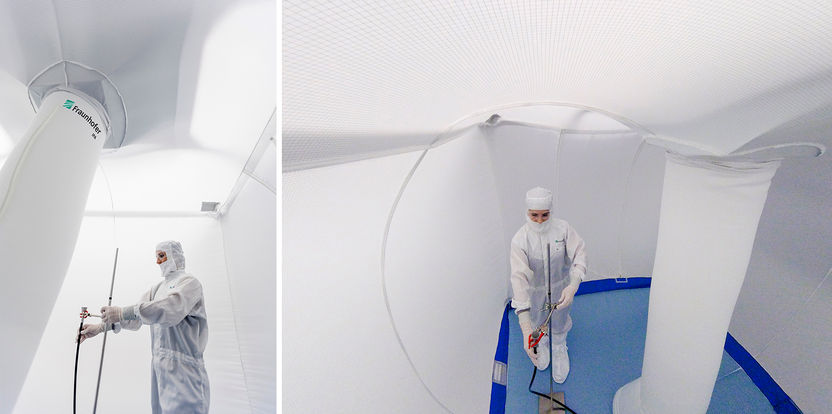

The “Clean Multipurpose Cover” is the world’s first flexible cleanroom system which protects products against contamination during transportation.

Fraunhofer IPA, Foto: Rainer Bez

The smallest degree of contamination can lead to major quality issues across many industries. Should, for example, any impurities occur on microchips, space probes and lenses, this can lead to defects or faulty end devices. To avoid damage, companies tend to outsource the relevant manufacturing and assembly steps for high-quality products to cleanrooms. However, these are expensive, limited in their availability and fail to offer protection against contamination as a result of transportation. Fraunhofer IPA has now developed the world’s first mobile cleanroom system in the form of its “Clean Multipurpose Cover”. It can be set up flexibly and ensures the sterility of products during transportation.

Particulate impurities and filmic contaminations incur additional costs in many industries. The semi-conductor, food, automotive, air and space exploration technology and pharmaceutical sectors, among others, may be affected by this. Tanja Meyer, Project Manager at Fraunhofer IPA, explains: “If products become contaminated, they are either rejected or must subsequently be cleaned.” Meyer goes on to clarify that if companies are unable to rely on the cleanliness of their manufacturing environment, retrospective analyses are required. Both are time and cost-intensive.

Companies bypass this problem by manufacturing sensitive products in cleanrooms. However, there are also problems involved in this. Meyer expands: “Not all companies, above all SMEs, have their own cleanroom available. Of course, they can rent one or have the parts cleaned externally, but this is not financially viable over the long term in many cases.” Furthermore, contamination can still occur during transportation. Static cleanrooms, as they exclusively are these days, cannot protect products outside of their own four walls. With this in mind, scientists at Fraunhofer IPA have already received regular requests from industry to develop a cost-effective, flexible solution.

Companies save energy and maintenance costs

The Stuttgart-based scientists have fulfilled these requirements with their “Clean Multipurpose Cover” solution. The world’s first flexible cleanroom system combines the technical cleanliness standards of a cleanroom with a product which can be set up quickly and simply wherever needed. In being operated “on demand”, the company is not subject to enforced occupancy rates which come with static cleanrooms, thereby making enormous savings in energy and maintenance costs. Another benefit is presented by the swift assembly time of under one hour. The flexible cleanroom solution can then be used immediately after a short start-up phase. Fraunhofer IPA developed an airflow concept for their system composed of low-TVOC and low abrasion materials with connected filter system. Meyer explains: “This enables us to guarantee a contamination-free manufacturing environment up to cleanliness class of ISO 3, certified in accordance with DIN ISO 14644-1.” The Clean Multipurpose Cover has a modular structure and can be individually configured as required. It is available in different sizes up to 4m2, with or without a floor. The constructed system can be transported, with a mid-range model weighing no more than 20kg. It is therefore fully functional.

Cleanroom feasibility confirmed in lab tests

In June 2016, scientists at Fraunhofer IPA produced the first prototype. “The tests conducted in the cleanroom laboratories of the Center for Contamination Control affirmed the operational capability of the solution,” Mayer was pleased to confirm. Companies can now order customer-specific models from Fraunhofer IPA. Our scientists have identified the requirements in exchanges with research and industry partners. Costs are determined on a customer-specific basis, varying according to requirements, size and air purity class. Currently, the Stuttgart-based scientists are working on further developing the system for industry and customer-specific requirements such as chemical and microbiological contaminants.

Other news from the department science

Get the life science industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

AI and 10 seconds of voice can screen for diabetes - Scientists discover voice tech as potential game changer in Type 2 diabetes detection

Dead on Target: Multifunctional nanoparticle platforms for targeting and imaging cancer cells

Santhera Presents New Data on MC-4R Antagonist Program for Treatment of Cancer Cachexia

Artie_Lange

Oncogenex Presented Study Showing Preliminary Results for Phase II Trial of OGX-011 in Advanced Prostate Cancer

Robert_Aldworth