BRAIN and Südzucker cooperate in the field of CO2 utilisation by microorganisms

BRAIN AG and Südzucker AG are intensifying their cooperation in the field of microbial utilisation of carbon dioxide. The cooperation, which is co-financed by the German Ministry of Education and Research (BMBF) as part of the strategic alliance ZeroCarbFP, aims at making the industrial by-product CO2 available for the production of a multitude of interesting intermediates using optimised platform organisms. During Phase 1 of the alliance, a two-stage process was successfully developed at laboratory scale. Based on these promising results, the two partners have now applied for further funding with the BMBF in order to scale up the process to a pilot facility at the Zeitz CO2-emitting bioethanol plant in Phase 2 of the strategic ZeroCarbFP Alliance.

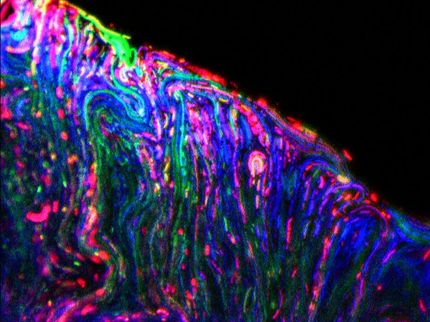

Optimisation of biotechnological fermentation processes of mono- and dicarboxylic acids using carbon-rich industrial waste streams.

© BRAIN AG, Zwingenberg

Bioethanol production plant of CropEnergies AG in Zeitz, a subsidiary of Südzucker: The resulting of CO2 in the production of BioEthanol is microbially bound will be converted to mono- and dicarboxylic acids

© Südzucker AG, Mannheim

Currently, the partners are pursuing the goal of using the CO2 generated during the production of bioethanol as material building block. The intermediate products generated from CO2, such as mono- and dicarboxylic acids, may then be utilised as specialty products in the bioplastics industry, which so far has been dependent on fossil resources.

“For many years, Südzucker AG has endeavoured to make its production processes as sustainable as possible with regard to yield and energy efficiency. We also have had much success when it comes to utilising carbonaceous side streams,” states Dr Wolfgang Wach, Head of Biotechnology at Südzucker’s Central Department for Research, Development, and Service (CRDS). “The cooperation with BRAIN perfectly complements our own research activities in the field of material use of CO2. In this context, we have just been able to successfully conclude a project studying algae as utilisers of carbon dioxide.“

“By cooperating with BRAIN AG we aim to place the material use of side streams in our industrial processes on a broader base. The first, highly promising results making use of the CO2 from bioethanol plants in microbial production confirm that we will achieve our goals together with our strategic partner, BRAIN,” says Edda Höfer, Project Manager in CRDS at Südzucker.

“We are delighted to have reached the first milestones in our cooperation using CO2 as a valuable resource. Based on the successfully established laboratory process we, together with our strategic partner, Südzucker, now intend to establish a first pilot facility at the existing bioethanol production site in Zeitz during Phase 2 of the ZeroCarbFP Alliance in order to pave the way for the sustainable use of side streams as resources,” says Dr Jürgen Eck, CEO of BRAIN AG. “In addition, we see the potential of using the technology, which we developed in cooperation with our partner, in other CO2-emitting processes as well, thus permitting us to make it available for widespread industrial use. The microorganisms are undemanding and can easily adapt to different sources of carbon dioxide.”

“This co-developed two-stage process of making material use of CO2 constitutes a major breakthrough. The temperature of the carbon dioxide gas, which is low compared to similar processes, enables significantly higher substrate availabilities. Correspondingly, we have achieved high carbon fixation rates by our first-stage microorganisms,” asserts Dr Jörg Mampel, Project Head and microbiologist at BRAIN. “In the second stage, we have been able to provide our partner, Südzucker, with an entire portfolio of interesting product candidates thanks to incorporating a platform organism. At BRAIN, we are truly delighted that we managed to establish the laboratory process in such a short time!”