Cell-free protein synthesis is potential lifesaver

Lives of soldiers and others injured in remote locations could be saved with a cell-free protein synthesis system developed at the Department of Energy's Oak Ridge National Laboratory.

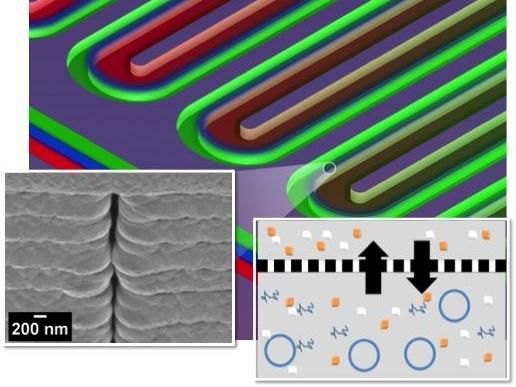

This section of a serpentine channel reactor shows the parallel reactor and feeder channels separated by a nanoporous membrane. At left is a single nanopore viewed from the side; at right is a diagram of metabolite exchange across the membrane.

ORNL

The device, a creation of a team led by Andrea Timm and Scott Retterer of the lab's Biosciences Division, uses microfabricated bioreactors to facilitate the on-demand production of therapeutic proteins for medicines and biopharmaceuticals. Making these miniature factories cell-free, which eliminates the maintenance of a living system, simplifies the process and lowers cost.

"With this approach, we can produce more protein faster, making our technology ideal for point-of-care use," Retterer said. "The fact it's cell-free reduces the infrastructure needed to produce the protein and opens the possibility of creating proteins when and where you need them, bypassing the challenge of keeping the proteins cold during shipment and storage."

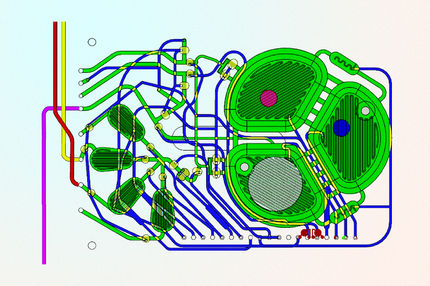

ORNL's bioreactor features elegance through a permeable nanoporous membrane and serpentine design fabricated using a combination of electron beam and photolithography and advanced material deposition processes. This design enables prolonged cell-free reactions for efficient production of proteins, making it easily adaptable for use in isolated locations and at disaster sites.

From a functional perspective, the design uses long serpentine channels integrated in a way to allow the exchange of materials between parallel reactor and feeder channels. With this approach, the team can control the exchange of metabolites, energy and species that inhibit production of the desired protein. Through other design features, researchers extend reaction times and improve yields.

"We show that the microscale bioreactor design produces higher protein yields than conventional tube-based batch formats and that product yields can be dramatically improved by facilitating small molecule exchange with the dual-channel bioreactor," the authors wrote.

The researchers also note that on-demand biologic synthesis would aid the production of drugs that are costly to mass-produce, including orphan drugs and personalized medicines.

Original publication

Other news from the department science

These products might interest you

New

New

Flexcell Zelldehnungsbioreaktoren für zelluläre Biomechanik-Anwendungen by Dunn

Cell Stretching Bioreactors for Life Science Research

Used in over 1300 laboratories worldwide, and cited in over 9000 research publications

Biostat STR by Sartorius

Biostat STR Generation 3 Bioreactors

Engineered for Ultimate Upstream Performance

Ambr® 250 HT Consumables by Sartorius

Efficient bioprocesses with single-use bioreactors

Minimise cleaning effort and maximise flexibility for cell and microbial cultures

Ambr® 250 Modular by Sartorius

Mini bioreactors for cell and gene therapies with high scalability

Maximise your process development with reliable single-use vessels

Get the life science industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.