Enzymes to become potential competitors for petroleum

Evonik researchers and scientists at Graz University discover biotechnology access to 1-alkenes

Researchers at the specialty chemicals company Evonik Industries, in cooperation with scientists at Graz University, have discovered a biocatalytic access to 1-alkenes such as propene and 1-butene. Such hydrocarbon compounds are considered as key substances for the chemical industry's sophisticated integrated production of high-quality products. For example, Evonik uses propene in the manufacture of superabsorbents or methionine, while 1-butene serves as a component in many types of polyethylene and can be used as a raw material for producing plasticizers.

Such source materials have thus far not been typically manufactured with the aid of biocatalysis. In the opinion of leading scientists, the expansion of biotechnological processes to base, bulk and numerous specialty chemicals remains a largely unresolved challenge to this day. Dr. Thomas Haas, head of the Science & Technology unit at Creavis, Evonik’s strategic innovation unit, says: "If we can succeed in developing technically and economically feasible solutions in this area, we would be able to efficiently combine biotechnological and petrochemical processes in the chemical industry in the form of integrated production for greater added value.”

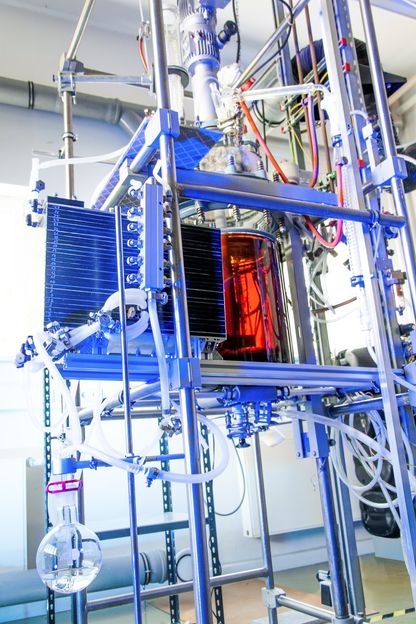

The industry researchers and the scientists working at Graz University under Professor Kurt Faber achieved a first breakthrough when they used naturally occurring short-chain alkanoic acids—saturated fatty acids produced by bacteria—as the source material for 1-alkenes. Haas notes: "It took the team a year to find an enzyme system for the optimal catalysis of converting the saturated fatty acids to 1-alkenes, ultimately with great success."

An established enzyme system, P450 monooxygenase OleT, catalyzes this chemical reaction—oxidative decarboxylation of alkanoic acids to 1-alkenes—very efficiently and substrate-specifically. Thanks to a cascade of two additional enzyme systems, the required electrons for oxidation are absorbed from oxygen in the air. Haas describes the next steps: "We are now working to transfer our enzyme combination to living cells. However, there is still a lot of work to do before we are ready for industry-scale production."

Haas and his team are consistently pursuing the goal of making renewable resources usable for the chemical industry with the help of biotechnology processes. “We will only be able to make equal use of fossil and biogenic raw material streams if we can find a way to incorporate biotechnological processes into integrated chemical production. This will help maintain and expand the industry's established and efficient value chains,” he explains.

Most read news

Topics

Organizations

Other news from the department science

Get the life science industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Sugar in western diets increases risk for breast cancer tumors and metastasis

Herceptin now approved in the EU for patients with HER2-positive advanced stomach cancer - First targeted biological therapy to show survival benefit in stomach cancer

Silence Therapeutics Forms Scientific Advisory Board

InteRNA Technologies and Dana-Farber Cancer Institute to collaborate on the role of microRNAs in cancer pathways

Bayer Animal Health and Paraco agree on access to lead molecules

Wiggly proteins guard the genome - Dynamic network in the pores of the nuclear envelope blocks dangerous invaders

Defective immune cells in the brain cause Alzheimer’s disease - Scientists are studying the role of immune cell activation in Alzheimer's disease

Sepsis in Children: Improved Diagnosis Thanks to New Global Criteria - Researchers applied machine-learning methods to extrapolate from the data analysis evidence-based criteria for diagnosing