Protein conjugation method offers new possibilities for biomaterials

Biological systems are at the source of many products designed to improve our lives. Recombinant DNA, for example, which retools molecules from multiple genetic sources for new purposes, has spurred the rise of life-changing therapeutics like unique blood-clotting proteins and synthetic insulin.

"Novel functional biomaterials make possible transformative new opportunities to impact society in a beneficial way," said Michael Jewett, associate professor of chemical and biological engineering at Northwestern University's McCormick School of Engineering. "Using the same types of machines used in cells to produce insulin proteins, my lab is exploring if we can create new types of protein polymers that might have utility in other applications and materials."

Jewett's group, along with the laboratory of Rachel O'Reilly, professor of chemistry at the University of Warwick in the United Kingdom, have taken an important step toward that goal by demonstrating a novel method in which certain kind of polymers can display new and unique functionalities.

Jian Li and Arnaz Ranji, postdoctoral associates in Jewett's lab, also contributed to the paper. The work was sponsored by the National Science Foundation Materials World Network program, DARPA, and the David and Lucille Packard Foundation.

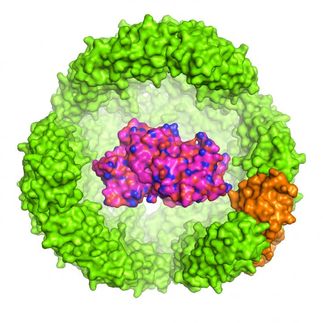

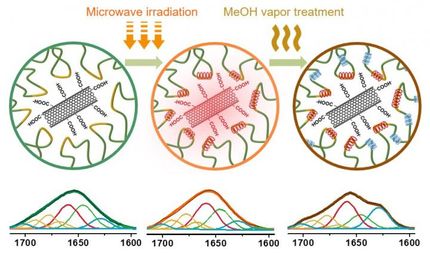

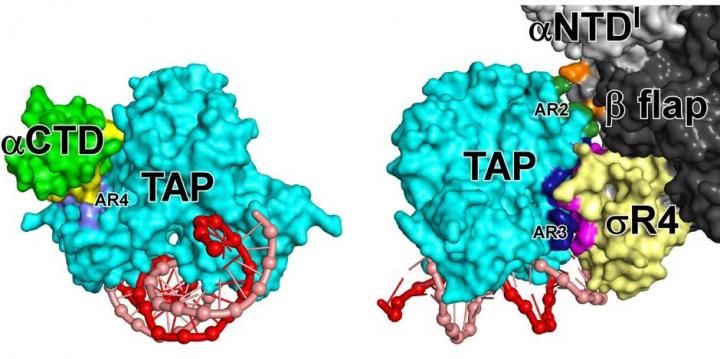

In the study, Jewett's team engineered two "handles" at opposite ends of a naturally derived biological compound, in this case a superfolder green fluorescent protein (sfGFP) found in jellyfish. The handles served as connection points for a pair of chemically-created polymers developed by O'Reilly, a co-corresponding author. The researchers then initiated a chemical process called bioconjugation, which linked the sfGFP protein and amino acids together through a chemical reaction, resulting in a new polymer.

"We imagined creating a protein polymer inside of cells that could be decorated with chemical polymers made by a chemist," said Jewett. "By essentially merging the best of biomolecular synthesis and the best of polymer chemistry, we felt we could endow the product with some kind of unique and functional behavior."

In analyzing the new material, the researchers made a surprising discovery: changing the position of the points of attachment on the sfGFP protein influenced the functional properties of the polymer --in this case temperature responsiveness--after it was conjugated. "This study gives a fascinating insight into the design of new biohybrid materials and highlights that fundamental materials properties can be readily tuned through rationale design," said O'Reilly.

"Historically, researchers have been limited by their ability to decorate proteins in a site-specific manner," said Jewett. "This work demonstrates we can decorate at multiple positions and identify for the first time that the way in which you choose to decorate a protein will impact its material behavior."

Jewett cautions that research in bioconjugate polymers is still in its early days, but believes the paper's takeaways could open the door for new levels of design for materials engineers to explore in the future. He's hopeful the field could eventually lead to the creation of new classes of polymers, including those that are responsive to multiple stimuli including those in nature.

"The notion of manufacturing responsive and self-healing materials are an exciting proposition for synthetic biologists," said Jewett. "Wouldn't it be great to have self-healing concrete paved in the streets of a city like Chicago? These are the types of possibilities that could be open to us in the future."