These microscopic fish are 3-D-printed to do more than swim

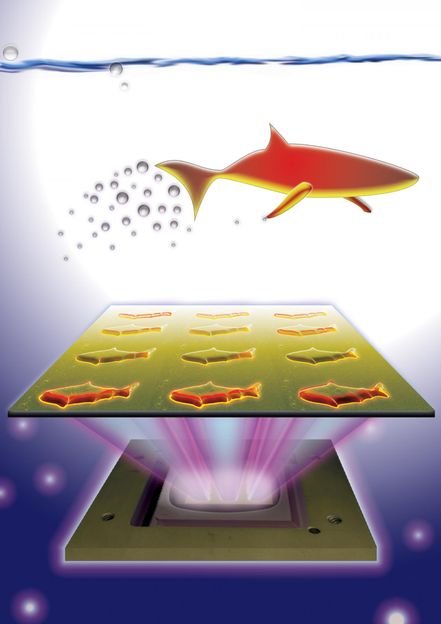

Nanoengineers at the University of California, San Diego used a 3D printing technology they developed to manufacture multipurpose fish-shaped microrobots that swim around efficiently in liquids, are chemically powered by hydrogen peroxide and magnetically controlled. These proof-of-concept synthetic microfish will inspire a new generation of "smart" microrobots, researchers said.

3-D-printed microfish contain functional nanoparticles that enable them to be self-propelled, chemically powered and magnetically steered. The microfish are also capable of removing and sensing toxins

J. Warner, UC San Diego Jacobs School of Engineering

The research was led by Professors Shaochen Chen and Joseph Wang of the NanoEngineering Department at the UC San Diego.

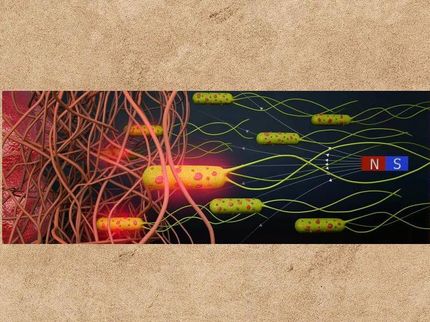

By combining Chen's 3D printing technology with Wang's expertise in microrobots, the team was able to custom-build microfish that can do more than simply swim around when placed in a solution containing hydrogen peroxide. Nanoengineers were able to easily add functional nanoparticles into certain parts of the microfish bodies. They installed platinum nanoparticles in the tails, which react with hydrogen peroxide to propel the microfish forward, and magnetic iron oxide nanoparticles in the heads, which allowed them to be steered with magnets.

"We have developed an entirely new method to engineer nature-inspired microscopic swimmers that have complex geometric structures and are smaller than the width of a human hair. With this method, we can easily integrate different functions inside these tiny robotic swimmers for a broad spectrum of applications," said the co-first author Wei Zhu, a nanoengineering Ph.D. student in Chen's research group at the Jacobs School of Engineering at UC San Diego.

As a proof-of-concept demonstration, the researchers incorporated toxin-neutralizing nanoparticles throughout the bodies of the microfish. Specifically, the researchers mixed in polydiacetylene (PDA) nanoparticles, which capture harmful pore-forming toxins such as the ones found in bee venom. The researchers noted that the powerful swimming of the microfish in solution greatly enhanced their ability to clean up toxins. When the PDA nanoparticles bind with toxin molecules, they become fluorescent and emit red-colored light. The team was able to monitor the detoxification ability of the microfish by the intensity of their red glow.

How this new 3D printing technology works

The new microfish fabrication method is based on a rapid, high-resolution 3D printing technology called microscale continuous optical printing (μCOP), which was developed in Chen's lab. Some of the benefits of the μCOP technology are speed, scalability, precision and flexibility. Within seconds, the researchers can print an array containing hundreds of microfish, each measuring 120 microns long and 30 microns thick. This process also does not require the use of harsh chemicals. Because the μCOP technology is digitized, the researchers could easily experiment with different designs for their microfish, including shark and manta ray shapes.

Original publication

Other news from the department science

These products might interest you

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

DynaPro Plate Reader III by Wyatt Technology

Screening of biopharmaceuticals and proteins with high-throughput dynamic light scattering (DLS)

Efficiently characterize your sample quality and stability from lead discovery to quality control

Get the life science industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.