NSF grant for engineering noses, jaws and ears

Laboratory-engineered noses, jaws and ears. The stuff science fiction is made of is coming soon from a University of Akron lab. With a $390,000 NSF grant, Matthew Becker, UA professor of polymer science and biomedical engineering, is developing 3-D-printed biodegradable polymer scaffolds, the frameworks within which bone will grow, with the hope of changing the face of craniofacial reconstruction.

Dr. Matthew Becker, professor of polymer science and biomedical engineering

Photo by Lauren Collins

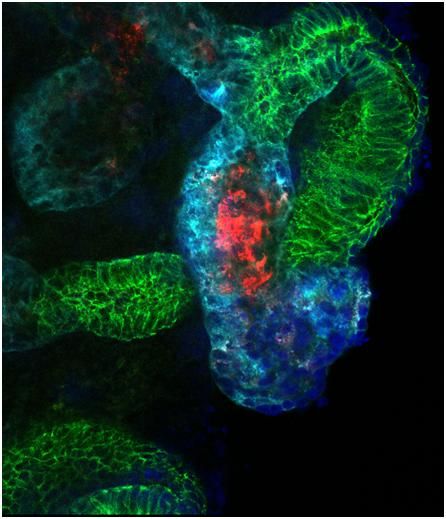

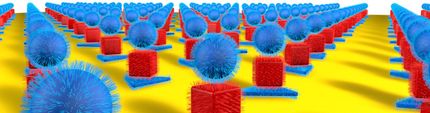

Functionalized with peptides and proteins on their surface, the polymer material is designed to accelerate bone generation. Imagine an infantry solder with a gunshot wound that shattered his jaw or a person born with a birth defect such as a missing nose. The absent bone is replaced by new bone, which grows on a polymer scaffold custom-designed via 3-D printing according to a patient's own MRI and CT scanned images. Applied under the skin by a reconstructive surgeon, the polymer scaffold breaks down into amino acids, carbon dioxide and normal body metabolites when the new bone sets.

Becker explains that the biodegradable polymer scaffolds come ready-made with functional groups on the surface that can be decorated with peptides and proteins that cause new bone to form. While previous 3-D printing technology has attempted to create such scaffolds, the diversity of polymer material used in the filament feed stocks has been limited, reducing the accessible chemical and physical properties that initiate bone growth.

"Recently we've discovered a combination of peptide concentrations capable of accelerating human mesenchymal stem cell differentiation into bone. We are now working on translating these peptides to our 3-D printed scaffolds without additives to make them functional exclusively on the surface, where the bone growth is necessary for head- and neck-injury applications," Becker says.

Most read news

Organizations

Other news from the department science

Get the life science industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

New separation process for key radiodiagnostic agent reduces radioactive waste - Less waste from lower enriched Uranium targets

Mace_(spray)

Cardiopulmonary_bypass