Central biobank for drug research

For the development of new drugs it is crucial to work with stem cells, as these allow scientists to study the effects of new active pharmaceutical ingredients. But it has always been difficult to derive enough stem cells of the right quality and in the right timeframe. A central biobank is about to remedy the situation.

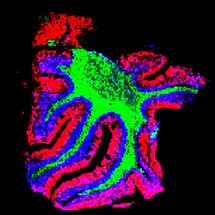

The biobank comprises three cryotanks, equipped with cooled protective hoods, and a transfer station from which the sample containers are transported via a rail system. There is enough space for approximately 60,000 samples.

© Fraunhofer IBMT

Human stem cells allow scientists to assess how patients are likely to respond to new drugs and to examine how illnesses come about. For a few years now, it has been possible to take tissue samples from adults and use reverse programming to artificially produce stem cells, which have the potential to create any kind of cell found in the human body. Before this discovery, pharmaceutical researchers had to use adult stem cells or primary cells, which have a more limited potential. Another option is to use stem cells derived from human embryos, but – quite apart from the ethical considerations – these cells are available only in limited diversity. The new technique makes it possible for instance to reprogram adult skin or blood cells so that they behave in a similar way to embryonic stem cells and can become any type of cell. “These are known as induced pluripotent stem cells, or iPS cells for short,” says Dr. Julia Neubauer from the Fraunhofer Institute for Biomedical Engineering IBMT in St. Ingbert, Germany. Although an increasing number of local biobanks have emerged in recent years, none of them fulfills the requirements of the pharmaceutical industry and research institutions. What is needed is a supply of ‘ready-to-use’ stem cells, which means large numbers of consistently characterized, systematically catalogued cells of suitable quality.

At the beginning of 2014, the IBMT teamed up with 26 industry and research partners to launch a project aimed at establishing a central biobank – the European Bank for induced pluripotent Stem Cells (EBiSC) – to generate iPS cells from patients with specific diseases or genetic mutations. Six months into the project and the first cells are available for use in the development of new drugs. By its three-year mark, it is hoped the project will be in a position to offer over 1000 defined and characterized cell lines comprising a hundred million cells. Such quantities are needed because a single drug screening involves testing several million cells. The main biobank facility is being built in the English city of Cambridge and an identical “mirror site” will be set up at the IBMT’s Sulzbach location in Germany.

Gently freezing cells

The IBMT was brought on board for EBiSC by virtue of the comprehensive expertise it gained through participation in the EU’s “Hyperlab” and “CRYSTAL” projects. For EBiSC, IBMT scientists are responsible for freezing the cells and for automating cell cultivation and the biobank itself. For an efficient long-term storage of functional stem cells, they have to be cooled down to temperatures of below 130 degrees Celsius in a controlled way. The scientists have to prepare the cells so they can survive the cold shock of nitrogen gas. The IBMT has, for instance, developed technologies that allow cells to be frozen in an extremely gentle way. “Cells don’t like being removed from the surface they are grown on, but that’s what people used to do in order to freeze them. Our method allows the cells to stay adherent,” explains Neubauer.

Just as with foodstuffs, stem cells depend on an unbroken cold chain to preserve their functionality and viability. The scientists store the cells in special containers – or cryotanks – each measuring one by two meters. To remove a particular sample, the scientists have to open the cryotank. The problem is that this exposes all the other samples to warmer ambient air, causing them to begin to thaw out. “It’s just like when you go to your refrigerator at home – it’s not a good idea to leave the door open too long,” says Neubauer. She and her colleagues at the IBMT and industry partner Askion GmbH have together developed a stem cell biobank complete with protective hoods that protect the other samples whenever the cryotank is opened. In addition to maintaining the temperature, the hoods help keep another key shelf-life criterion, humidity, at a constant level.

Flawless freezing is important, but it is just as important to automate the whole process. “That not only guarantees consistency, it’s what makes it possible to provide large quantities of cells of the required quality in the first place,” says Neubauer. And the scientists’ cooling process already boasts a finished technology. In their automated biobank, each cell sample is labelled with barcodes to allow them to be tracked. The samples travel along a conveyor belt to the individual cyrotanks, and a computer monitors the entire freezing and storage process.

Now the scientists are working on automating cell cultivation – or the multiplying of the cells. There are essentially two possible approaches. One is to use robots that translate each preparation step into a mechanical one. The other is to use stirred bioreactors that provide free-moving cells with the ideal supply of nutrients and oxygen. Both technologies feature in the IBMT’s portfolio. “By the time the project is completed, we’ll know which is the better method for what we’re trying to do,” says Neubauer.