A hydrogel that knows when to go

Rice University bioscaffold material degrades as bone grows to replace it

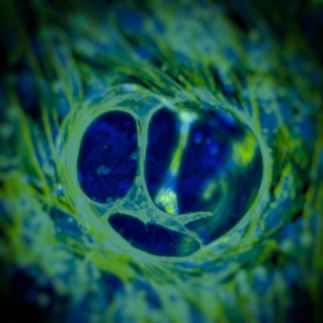

Rice University bioengineers have created a hydrogel that instantly turns from liquid to semisolid at close to body temperature – and then degrades at precisely the right pace.

The gel shows potential as a bioscaffold to support the regrowth of bone and other three-dimensional tissues in a patient’s body using the patient’s own cells to seed the process.

The hydrogel created in the lab of Rice bioengineer Antonios Mikos is a liquid at room temperature but, when injected into a patient, becomes a gel that would fill and stabilize a space while natural tissue grows to replace it.

The new material detailed in the American Chemical Society journal Biomacromolecules takes the state of the art a few steps further, Rice scientists said.

“This study describes the development of a novel thermogelling hydrogel for stem cell delivery that can be injected into skeletal defects to induce bone regeneration and that can be degraded and eliminated from the body as new bone tissue forms and matures,” said Mikos, Rice’s Louis Calder Professor of Bioengineering and Chemical and Biomolecular Engineering.

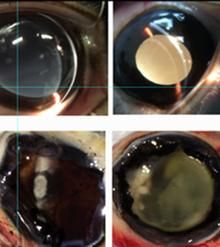

A problem with thermogelling polymers is that once they harden, they begin to collapse and then force out water, said Rice graduate student and the paper’s lead author, Brendan Watson. That process, known as syneresis, defeats the purpose of defining the space doctors hope to fill with new tissue.

“If the transition gellation temperature is one or two degrees below body temperature, these polymers slowly start to expel water and shrink down until they’re one-half or one-third the size. Then the defect-filling goal is no longer accomplished,” he said.

Watson and his colleagues at Rice’s BioScience Research Collaborative solved the problem by adding chemical cross-linkers to the gel’s molecules. “It’s a secondary mechanism that, after the initial thermogellation, begins to stabilize the gel,” he said. The links begin to form at the same time as the gel, but crosslinking takes up to a half-hour to complete.

The hydrogel is designed for stability over its long-term use as a scaffold for cells to take root and proliferate. But it’s also designed for its own timely destruction.

“I came up with the idea a few years ago, but it’s finally all come together,” said Watson, who is pursuing both a Rice doctorate and a medical degree in a joint program with nearby Baylor College of Medicine. “These chemical crosslinks are attached by phosphate ester bonds, which can be degraded by catalysts – in particular, alkaline phosphatase — that are naturally produced by bone tissue.

“The catalysts are naturally present in your body at all times, in low levels. But in areas of newly formed bone, they actually get to much higher levels,” he said. “So what we get is a semismart material for bone-tissue engineering. As new bone is formed, the gel should degrade more quickly in that area to allow even more space for bone to form.”

The fine balancing act took a lot of expertise from his colleagues and co-authors, including Paul Engel, chair of Rice’s Department of Chemistry, and F. Kurtis Kasper, a senior faculty fellow in bioengineering. “It looks like we may have just decided to try something and found that, hey, it worked! But that wasn’t the case,” said Watson, describing the months and years it took to refine the hydrogel. Engel’s help with the sophisticated chemistry was especially valuable, he said.

Watson expects that the material degradation can be tuned to match various bone growth rates.

“Optimizing the degradation kinetics is nontrivial and may be better suited for a biotech company,” he said. “We focus more on the performance of the hydrogels and the underlying molecular mechanisms”