Research Alliance for the microbial production and applica-tion of biopolymers

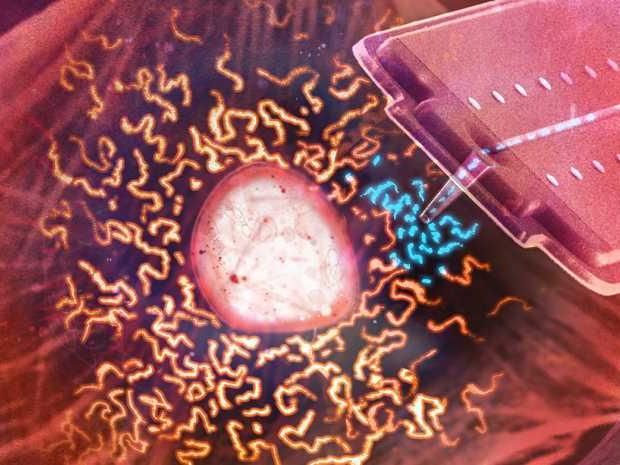

The four partners BRAIN, the Hohenstein Institute, Kelheim Fibres and rökona, announce the formation of a new research alliance for the biotechnical production and modification of specialty algi-nates. The aim of the alliance is to establish a sustainable micro-bial bioprocess for the production of specialised alginate compo-nents. The biopolymers should serve a dual purpose: application in high-quality medical product matrices and within the textile industry.

The biopolymer products will be used in both topical and wound-phase specific dressings, as well as for application-specific modification of matrices in technical textiles. Aside from high purity and more defined material properties of the biopolymer, the advantage of microbial pro-duction processes is an improvement in the environmental efficiency of products. Parts of the alliance research project will be co-financed by the Federal Ministry of Education and Research (BMBF) under grant number 013A126 and the acronym AlBioTex.

"Alongside our partners in the alliance, we want to build a high-quality bio-based matrix system and at the same time, a sustainable process in terms of the yield and techno-functionality of the biopolymers", ex-plains Dr. Guido Meurer, Unit Head Microbial Production Technologies at BRAIN. “BRAIN has been an active researcher of innovative, sup-portive, bioactive substances for use in medical products for several years. These substances are then introduced into appropriate biologi-cal matrices and ultimately into modern wound dressings.“

The primary objective of BRAIN, alongside the Hohenstein Institute, is to develop microbial production organisms for application in industrial quantities of biopolymers in appropriate biofermentation processes on an industrial scale. These research results also assist in the common aim of developing innovative nonwoven materials.

"Until now, the variation and optimisation of the material properties of alginate was either not possible at all, or only possible with immense effort. Through the use of biotechnology, a differentiated use of algi-nates is made possible in the specialised textile field for the first time", says Dr. Timo Hammer, Head of Research in the Department of Hy-giene, Environment and Medicine at the Hohenstein Institute, and co-ordinator of the AlBioTex project.

The partners Kelheim Fibres and rökona Textilwerk participate in the alliance by providing access to high-quality, homogeneous biopoly-mers. The plan is to develop functional textiles with new properties and to use them in pilot processes.

"The production of high-quality and homogeneous biopolymers is cru-cial for our functional viscose fibres based on renewable resources. Various functionalities expand this range of innovative fibre properties for new high-tech applications", says Walter Roggenstein, Head of Re-search and Development at Kelheim Fibres GmbH.

"The joint research in these two fields, the textile and medical technology industries, is another prime example of the intensification of the biologisation of industries", concludes Dr. Holger Zinke, CEO of BRAIN, the motivation behind the research alliance. "Biological knowl-edge is the driving force of the bioeconomy and industrial biotechnol-ogy is one of its most important fields."

Most read news

Organizations

Other news from the department science

Get the life science industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Scientists create 'nano-reactor' for the production of hydrogen biofuel

Sitosterolemia

Category:Neurologists

Isotopic_dilution

Detect neurodegenerative diseases such as Alzheimer's by a simple eye scan? - Milestone on the way to early diagnostics: Researchers use spectroscopic means to decipher the biochemical composition of the retina

Leland_H._Hartwell

How plague pathogens trick the immune system - Researchers show how an enzyme changes its shape and promotes the infection

X-ray eyes peer deeper into deadly pathogen

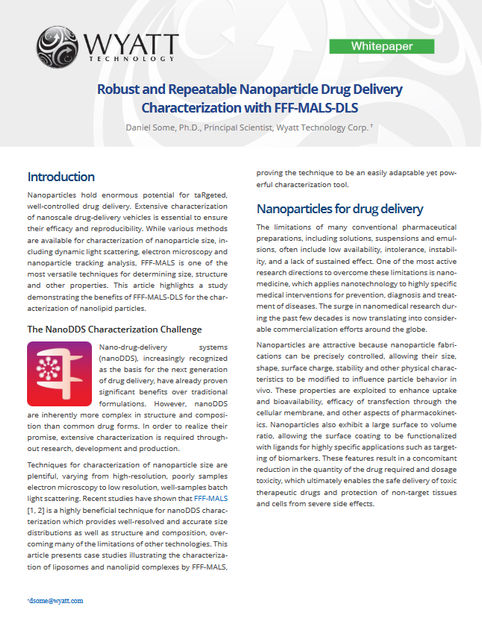

Robust and Repeatable Nanoparticle Drug Delivery Characterization with FFF-MALS-DLS -

A new dimension in transplantation - Technique to transplant mitochondria from one living cell to another

Scientists see anti-aging potential in an invasive weed - Cocklebur extracts could protect skin, speed wound healing and ward off wrinkles