Frost & Sullivan: Opportunities for electronics manufacturing services in medical industry increasing

The need for OEMs to keep up with rapid technical advancements boosts outsourcing opportunities for electronics manufacturing service providers

Advertisement

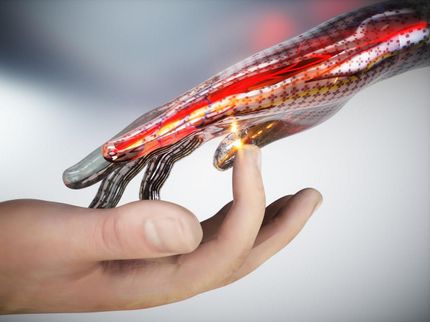

Original equipment manufacturers (OEMs) are increasingly turning to electronics manufacturing service (EMS) providers to better handle the escalating volumes of electronic content in the medical industry. With opportunities for high-level product assembly and complete build projects expected to increase, the potential for EMS in the medical industry will progress gradually over the next few years.

New analysis from Frost & Sullivan, EMS Opportunities in the Medical Industry, finds that the market earned revenues of more than $16.43 billion in 2012 and estimates this to reach $34.38 billion in 2019.

“The challenge in maintaining certified, state-of-the-art manufacturing facilities and complex supply chain operations is that it strains OEMs’ profit margins, compelling them to adopt EMS,” says Frost & Sullivan Research Analyst Lavanya Rammohan. “EMS providers, with their exposure to various verticals, are the ideal solution to manage the electronics boom in healthcare brought about by the use of wireless communications, robotics and software.”

Rising demand for engineering support as well as improving EMS competencies in product introduction, manufacture design and value-add services will boost EMS growth in the medical industry.

However, despite EMS providers’ growing expertise, the risk of liabilities prevents OEMs from outsourcing several services. Stringent regulations place medical OEMs under huge scrutiny, thereby limiting their outsourcing to tactical operations, such as printed circuit board assembly and sub-system assembly.

Strict regulations also lengthen the outsourcing cycle, as OEMs are cautious in decision-making and favor EMS vendors with proven expertise. Manufacturers’ preference to retain intellectual property and strategic customer touch points reduces revenue possibilities for EMS dealers.

“EMS suppliers need to focus on developing strong relationships with original equipment manufacturers to build trust and capability, as OEM-EMS partnerships require long-term commitment in order for outsourcing to increase,” concludes Rammohan. “Service providers must be aware of industry trends, including financial models, long sales realization cycles, manufacturing challenges, supply chain complexities, certifications and audits, to offer all-round services.”