An enzyme in training camp: Capturing and using CO2 efficiently

‘Lactyl-CoA mutase’, which is not found in nature, was specifically developed for efficient synthetic metabolic pathways

A team of researchers led by Prof. Tobias Erb at the Max Planck Institute for Terrestrial Microbiology in Marburg has succeeded in developing a new enzyme. The 'lactyl-CoA mutase' can efficiently convert a key metabolic compound into valuable products. To achieve this, the research team used evolution to train the abilities of a natural enzyme in the laboratory. The aim of the research is, among others, to find a future application in the capture and sustainable use of the greenhouse gas CO2.

Few building blocks in cellular metabolism are as central and versatile as acetyl-coenzyme A (acetyl-CoA). As a product of many CO2 fixation pathways, its utilization in the cell determines how much biomass can be formed, ultimately affecting how efficiently the greenhouse gas CO2 can be utilized in biotechnological processes.

To create other products and chemicals from acetyl-CoA, it must often first be converted into cellular intermediates with three carbon atoms, such as pyruvate. In nature, metabolic pathways for this process are either inefficient, involve many steps, or only work in the absence of oxygen. This means that when converting acetyl-CoA to pyruvate, either valuable carbon is lost, or the pathways are so long that they waste cellular resources.

For this reason, the team led by Tobias Erb at the Max Planck Institute in Marburg set out to create a new, efficient metabolic “bridge” between acetyl-CoA and pyruvate, one that would also enable an effective capture and utilization of the greenhouse gas CO2. The study was a collaboration with researchers from the Max Planck Institute for Molecular Plant Physiology in Potsdam, and has now been published in the scientific journal Nature Communications.

A search sparked by Theoretical Design

In synthetic biology, new metabolic pathways are first designed on paper before being tested in the lab. For this project, the team initially outlined a theoretical metabolic route that would bind additional CO2 while being shorter than previously known pathways.

The challenge was that the key enzyme activity required for this process, known as "Lactyl-CoA mutase," was purely theoretical at first. This activity had not yet been described in nature. Searching enzyme databases, the team identified a promising candidate whose structure seemed suitable for the desired process. In experiments, this enzyme could indeed act on the provided substrate - but it worked extremely slowly.

How Do You Train a Slow Enzyme?

"In nature, constant adaptation driven by mutations and selection lead to improved traits over time. We harnessed this process in a sped-up version in the lab to optimize our enzyme," explains Helena Schulz-Mirbach, a doctoral researcher in Tobias Erb's team and one of the study's first authors. "To prevent the newly gained ability from being lost through further mutations, we coupled the growth of a modified Escherichia coli bacterium to the desired enzyme activity. Developing a strain that could use this slow enzyme for its growth was anything but trivial."

Training in a Living Organism

In the second step, this strain was subjected to accelerated evolution in the lab, a process called "adaptive laboratory evolution (ALE)." Mutations were introduced and then selected based on desirable traits. The resulting variants of Lactyl-CoA mutase were not only faster and supported better growth in the strain but – crucially – they also functioned outside the bacteria in a simplified chemical process in the test tube (in vitro). Here, the improved enzyme demonstrated a 5- to 10-times better performance compared to its natural precursor.

"Our study is a prime example of how we can utilize the mechanisms of metabolism and evolution in living cells to optimize a desired property for applications in synthetic biology and cell-free biochemistry. Only by combining these approaches were we able to identify improved enzyme variants," says Philipp Wichmann, who led the in vitro work in the study.

Further Optimization and Research Goals

"However, our enzyme still needs to be improved: Compared to other enzymes in nature, Lactyl-CoA mutase is still quite slow," adds Dr. Ari Satanowski, who helped design and lead the project. A major goal of future research will be to make this enzyme faster so that it can be used in various applications. This entirely new metabolic route between acetyl-CoA and pyruvate opens up new possibilities, such as producing 3-hydroxypropionate, a precursor for sustainable, biologically derived plastics.

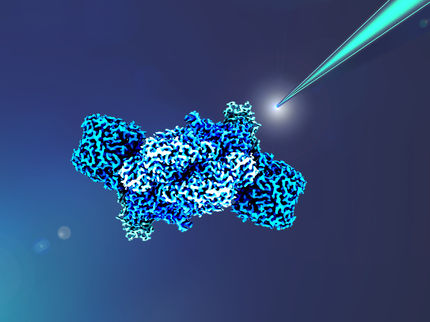

"We also want to learn more about the enzyme itself," says Helena Schulz-Mirbach. "While we know which mutations improved its activity, we don’t yet understand how exactly they achieved this. By resolving the enzyme's structure, we hope to uncover more about its reaction mechanism and the effects of these mutations."

Original publication

Helena Schulz-Mirbach, Philipp Wichmann, Ari Satanowski, Helen Meusel, Tong Wu, Maren Nattermann, Simon Burgener, Nicole Paczia, Arren Bar-Even, Tobias J. Erb; "New-to-nature CO2-dependent acetyl-CoA assimilation enabled by an engineered B12-dependent acyl-CoA mutase"; Nature Communications, Volume 15, 2024-11-26