Better standard for laboratory analysis

Spin-off PHABIOC develops innovative laboratory equipment for pharmaceutical and biotech research

Greater efficiency, speed and precision in laboratory analyses as well as drastically reduced material consumption: with the SpecPlate, the spin-off PHABIOC from the Karlsruhe Institute of Technology (KIT) is replacing up to four conventional sample carriers with an innovative design. Series production is now starting.

Precise information about the composition and concentration of samples is crucial in the development of drugs and active ingredients, for example. For quality assurance in high-throughput processes, microtitre plates made of high-quality plastics have so far been used as standardized sample carriers, which are then disposed of. In order to reduce this extreme consumption of resources in the laboratory, but also to speed up the analyses, the KIT spin-off PHABIOC has developed the SpecPlate as an advanced microtiter plate. "Thanks to its closed, step-like measuring chambers, the SpecPlate enables four independent measurements in each sample," says Dr. Carsten Radtke, co-founder of PHABIOC GmbH and former researcher at the Institute of Bio- and Food Technology (BLT) at KIT. "This means up to 75 percent less consumption of laboratory materials and a reduction in process time by two thirds. This enables laboratories to carry out faster, more cost-effective and more sustainable analyses."

Maximum precision and compatibility

The SpecPlate uses only a small amount of sample material for a measurement - just 36 microliters are required. The special design ensures that the liquid fills the measuring chambers precisely and that no measuring errors can occur due to inaccurate pipetting or the shape of the liquid surface. The different chambers also allow measurements to be taken in a wide concentration range without the need for dilutions. "Compatibility with industry standards, such as automated pipetting systems and plate readers, is particularly advantageous," emphasizes Radtke. The inlets of the measuring structures and the measuring chambers are precisely positioned in the grid of commercially available microtiter plates. This enables the SpecPlate to be seamlessly integrated into established laboratory systems and processes. "Our technology is based on standard market solutions, but addresses their susceptibility to errors and limitations. We therefore see the SpecPlate as the better standard."

Developed through research at KIT

The SpecPlate was originally developed in a working group led by Professor Jürgen Hubbuch (BLT). Together with partners from industry, it was then brought to market maturity. A production partner in Germany ensures high product quality as well as short delivery and communication channels. "Even during the pilot phase, the SpecPlate received positive feedback from pilot customers, including some of the leading pharmaceutical companies," says PHABIOC founder Carsten Radtke.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Most read news

Other news from the department business & finance

Get the life science industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Something is happening in the life science industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.

Last viewed contents

First_Person_Plural

Enaptin

Inner_Wheel_Club

Olanzapine

B-cell_leukemia

Diaporthe_phaseolorum_var._sojae

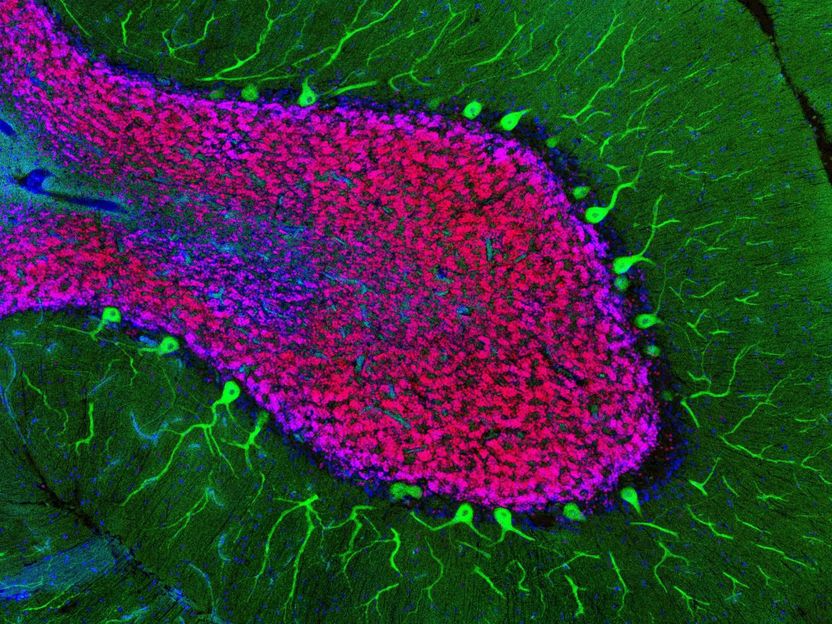

New method for studying gene expression could improve understanding of brain disease

Blood thinners on 'as needed' basis is safe and effective for lowering stroke risk as compared to long-term use - Researchers find anticoagulants, routine pulse monitoring effective in treating atrial fibrillation