Affordable bioprinting: tissue at the touch of a button

Modified 3D printer from the electronics store prints living tissue

Advertisement

Researchers have now succeeded in modifying a simple 3D printer so that it can create biological structures at the touch of a button. This is an opportunity for small laboratories to conduct research in this area too.

"Tissue engineering is a technology of the future," Benedikt Kaufmann is convinced. Artificially produced, functional tissue - for example cartilage, bone or muscle tissue - potentially offers a wealth of potential applications: for example in pharmacology, where the benefits and side effects of drugs need to be investigated; or in medicine for the treatment of patients with tissue damage. However, the production of complex tissue that has the same properties as natural tissue is difficult.

For several decades, researchers have been using various 3D printing techniques to produce organic structures from biomaterials and cells, which are then prepared for their later function through targeted training. "But despite all our successes, we are still a long way from our goal of producing customized tissue on a larger scale. In order to further develop tissue engineering, researchers all over the world need to cooperate, generate and share knowledge," emphasizes the bioengineer at the Center for Applied Tissue Engineering and Regenerative Medicine (CANTER) at Munich University of Applied Sciences.

From the idea to the finished product

Until now, research has sometimes failed - even before it has begun - because of the budget: bioprinters, which can be used to produce three-dimensional cell structures, cost tens of thousands of euros. They are often unaffordable for small laboratories or institutes. As part of his doctorate, Kaufmann has now developed a cost-effective alternative: Together with an interdisciplinary team at CANTER in cooperation with the Technical University of Munich, he has modified a 3D printer from the electrical market, which costs a few hundred euros and is normally used to produce plastic prototypes and models, so that it can be used to print living tissue. The open source construction manual is now available to everyone free of charge.

Decisive factors: Heat and humidity

"The biggest challenge was creating suitable environmental conditions," recalls Kaufmann: "To process proteins and cells, you need high humidity and a constant 37 degrees Celsius. After extensive testing, the researchers decided on an efficient and cost-effective solution: heating foils, glued to the printer's aluminum housing and controlled by a microcontroller, heat the interior to the desired temperature. Water-soaked cellulose generates a humidity level of over 90 percent. The researchers also replaced the printer's printing platform, on which structures are built up layer by layer: In commercially available printers that process plastic, this plate is made of metal. The modified 3D printer has a suspension to which a small glass plate can be attached. Biomaterials and cells can be printed directly onto this translucent plate and then examined in high resolution under a microscope.

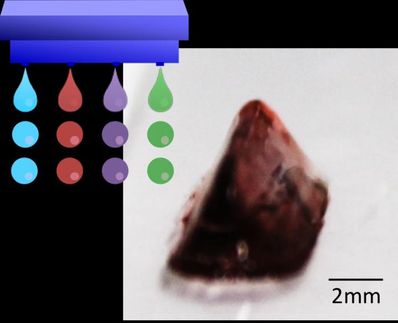

The very small printer works with masked stereolithography, a particularly cell-friendly process in which light from LEDs is projected through a liquid crystal display - similar to that of a cell phone or computer monitor - onto the glass platelet wetted with a gelatine-like hydrogel according to a pre-programmed pattern. Individual pixels of the display are activated in a targeted manner, ensuring that the proteins in the hydrogel cross-link and harden at precisely the desired points - creating a three-dimensional structure layer by layer.

Tailor-made structures

Next to the professional laboratory equipment in the CANTER laboratory at Munich University of Applied Sciences, the converted 3D printer looks almost dwarfish. However, the results it delivers are not inferior to those of the large-scale devices: "Our tests have shown that the modified 3D printer can be used to produce organic structural scaffolds with varying degrees of rigidity - this is important because bone substance, for example, requires a higher degree of hardness than muscle tissue," says Kaufmann. It has now also been possible to integrate stem cells directly into the structures during the printing process.

This is good news for teams of researchers who previously had no way of producing tissue constructs themselves: They can now convert a simple commercially available 3D printer into a bioprinter thanks to the building instructions available online. "No engineering know-how is required for this," emphasizes Kaufmann. This paves the way for small laboratories to gain experience in the production, characterization and optimization of artificial tissue and to generate and share knowledge in order to further develop tissue engineering. The modified printer can even be used in schools to gain initial experience in 3D printing of biomaterials.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.