Enzymes instead of highly toxic cyanide

Researchers develop biocatalytic process for nitrile production

A research team from TU Graz and the Czech Academy of Sciences has used two enzymes to eliminate the need for highly toxic cyanide in the production of nitriles.

If the household cleaner emits a lemon-like odour, this may be due to a nitrile called citronellyl nitrile. These versatile chemical nitrile groups are also used in the manufacture of active pharmaceutical ingredients, superglue and chemical-resistant gloves. The prevalent production process used so far has required a chemical reaction of certain molecules with highly toxic cyanide. Margit Winkler from the Institute of Molecular Biotechnology at TU Graz, together with Ludmila Martínková from the Institute of Microbiology at the Czech Academy of Sciences, has now developed a biocatalytic process that does not require cyanide, works at room temperature and therefore requires less energy and produces less harmful waste. The project was funded by the Austrian Science Fund FWF and the Czech Science Foundation (GACR).

Two enzyme-guided steps

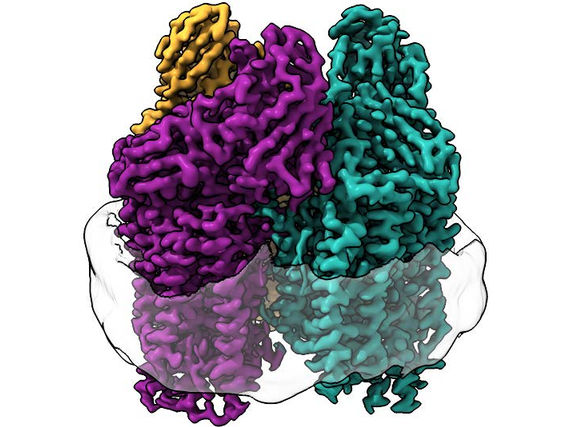

To replace the cyanide, the research group uses enzymes and combines three individual reactions into a cascade. The starting materials are carboxylic acids, such as fatty acids from plant oils or lignin, which is a by-product of wood processing. In the first step, the carboxylic acid is converted to an aldehyde by adding sugar, oxygen and the enzyme carboxylate reductase contained in living bacterial cells. However, this aldehyde is highly reactive and therefore unstable, and in many cases also volatile. To capture this substance, the aldehyde is allowed to react with hydroxylamine, which converts it into oxime, which is stable.

Oxime is a ‘watered’ form of nitrile, which is why the enzyme aldoxime dehydratase is used in the final step. This enzyme is also confined in bacterial cells and is responsible for water abstraction from the oxime. Once this has been done, the cascade has achieved its objective and the desired nitrile has been produced.

This method can now be used for the preparation of small nitrile quantities. This is already a promising technology for very potent fragrances, for example, of which only a small amount is needed to achieve an effect. Optimisation work is still required for the production of larger quantities of nitrile in order to be able to use the biocatalytic process at reasonable costs. Currently, highly diluted solutions are used in the first process step and a large reactor would be required to produce large quantities, which is not economic yet. Margit Winkler is therefore already conducting research on how to make the first step more efficient. Dehydration of the oxime alone, on the other hand, is extremely efficient and already reached technical maturity for production today.

A bio-based process

“I’ve been interested in cyanide chemistry ever since I wrote my master thesis, and as we know from Agatha Christie’s novels, cyanide is highly toxic,” says Margit Winkler. “It was therefore important for us to find a way to avoid this hazardous substance in production. The fatty acids we use come from vegetable oils. So, we really do have a bio-based production method here. We would now like to improve it even further so that it can be used widely.”

Most read news

Topics

Organizations

Other news from the department science

Get the life science industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

HNP Mikrosysteme GmbH - Schwerin, Germany

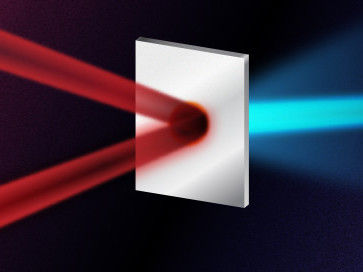

Colliding lasers double the energy of proton beams

Dr._Williams'_Pink_Pills_for_Pale_People

List_of_Symphytognathidae_species

Pulmonary_Hypertension_Association

Saliva

Friedrich_Schultze