Sustainable raw materials for a green chemical industry

Launch of the BEFuel project: From exhaust gases and wastewater to e-fuels and high-quality chemicals

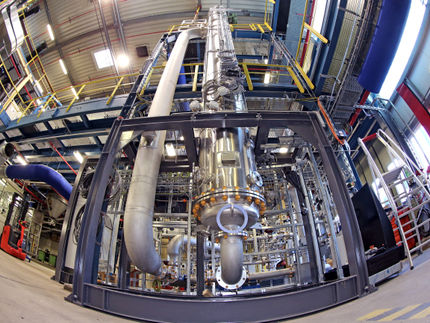

How can e-fuels and biosurfactants for industry be produced from exhaust gases and wastewater? An interdisciplinary consortium coordinated by Fraunhofer UMSICHT is addressing this question in the newly launched BEFuel project. The focus is on coupled bioelectrochemical production – i.e. the combination of electrochemical synthesis and biotechnological synthesis using microorganisms.

Two different waste streams are used for electrolysis powered by renewable energy: Crude glycerine, a waste material from biodiesel production, is used at the anode. The oxidation products can be used by microorganisms as nutrients to form biosurfactants. At the cathode, the researchers use waste water from a sewage treatment plant. Here, green hydrogen is initially produced, which the microorganisms use as an energy source to fix carbon dioxide in a first step and produce organic C6 and C8 acids in a second step. These can be used as starting materials for the production of biodiesel and biogas and are separated and enriched using special membrane technology.

Unique coupling of electrochemical processes

"This coupling of bioelectric systems for the simultaneous bioconversion of several waste streams is unique," says project coordinator Dr. Daniel Siegmund from Fraunhofer UMSICHT. "It enables the parallel production of several high-quality goods, reduces operating costs and increases energy conversion efficiency at the same time." Further advantages: The new system is both independent of imports and can be decentralized. In addition, nutrients from domestic wastewater and organic waste can be recycled thanks to the integration with existing sewage treatment plants, which can provide CO2 from flue gases or biogases as well as nutrients for the growth of biomass.

A team of different partners is responsible for the implementation and enables the interaction between electrolysis, biotechnological processing and product insulation as well as economic and ecological evaluation. In addition to Fraunhofer UMSICHT, these partners include Ruhr University Bochum with various chairs, SolarSpring GmbH, the Emschergenossenschaft and the Institute for Automation and Communication. Their success is measured by a comprehensive evaluation of the process. In addition to greenhouse gas emission balances and cost calculations, it also includes social and, above all, ecological aspects in order to determine the potential for short-term industrial application after project completion.

The project "BEFuel – Coupled bioelectrochemical production of e-fuels and high-quality chemicals from exhaust gases and wastewater" is funded by the Federal Ministry of Education and Research as part of the measure "Climate-neutral products through biotechnology – CO2 and C1 compounds as sustainable raw materials for the industrial bioeconomy (CO2BioTech)".

ProjectT Partners

- Ruhr-Universität Bochum | Lehrstuhl für Siedlungswasserwirtschaft und Umwelttechnik

- SolarSpring GmbH

- Emschergenossenschaft Lippeverband (EGLV)

- Institut für Automation und Kommunikation e.V. (ifak)

- Ruhr-Universität Bochum | Anorganische Chemie

- Ruhr-Universität Bochum | Mikrobielle Biotechnologie

Most read news

Topics

Organizations

Other news from the department science

Get the life science industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.