Nanomembranes with pore molecules for efficient filtration

Method offers the promise of many possible applications across the chemical and pharmaceutical industries

A team from Bielefeld University, Queen Mary University of London, Imperial College London (both United Kingdom) and Northwestern University in Evanston (USA) have produced a new breed of polymer nanomembranes with aligned supramolecular macrocycle molecules. These new nanomembranes demonstrate properties that promise to improve the efficiency of separation processes widely used across the chemical and pharmaceutical industries.

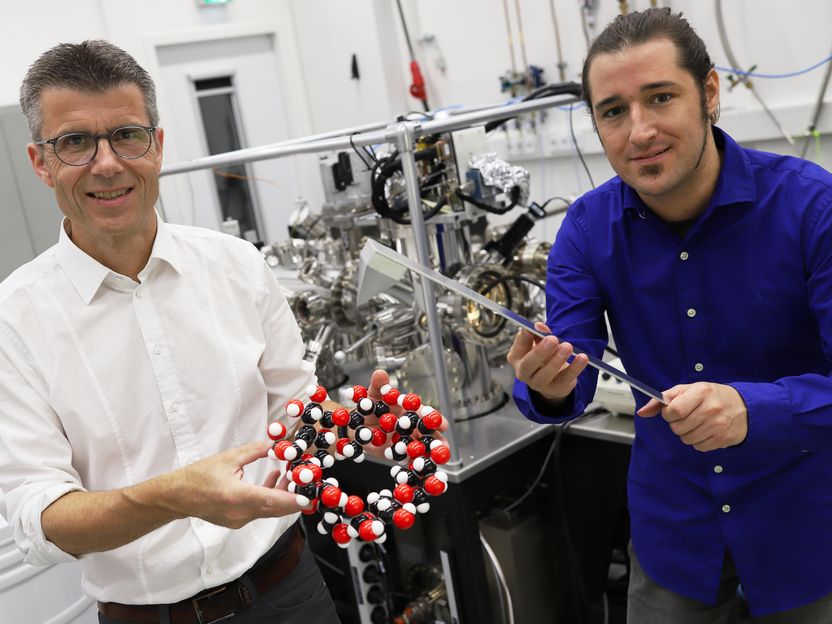

Professor Dr Dario Anselmetti of Bielefeld University with a sphere model of a cyclodextrin molecule—the basis of the new nanomembranes. Doctoral student Niklas Biere holds the model of the force sensor used to scan the membrane.

Universität Bielefeld/C. Pelargus

Conventional chemical and pharmaceutical industries use 45 until 55 per cent of their total energy consumption during production in molecular separations. In order to make these processes more efficient, cost-effective, environmentally friendly and therefore sustainable, these processes need to be partially or wholly replaced by novel separation strategies that make use of innovative and ground-breaking membrane technologies.

Publishing their results in the journal Nature, the team show that their polymer nanomembranes with aligned supramolecular macrocycles exhibit superb and extremely selective filtration properties that exceed the conventional polymer nanomembranes currently used across the chemical and pharmaceutical industries. Conventional polymer nanomembranes have a broad distribution of the pore size that lacks a controllable way to be precisely tuned.

Common filter materials are not very selective and also have to be operated in an energy-intensive manner using high pressures. ‘In order to turn these processes into more energy-efficient, cost-effective, environmentally compatible and thus sustainable processes, new separation and filtration methods must be developed,’ says Professor Dr Dario Anselmetti from the Faculty of Physics at Bielefeld University. ‘Our nanomembranes are only a few molecular layers thin, more defined by their architecture, and therefore much more energy efficient and selective.’

Method offers the promise of many possible applications

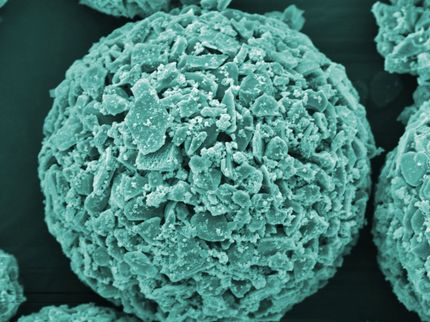

In this new breed of polymer nanomembranes, the molecularly predefined macrocycles are aligned to provide sub-nanometer pores as a highly effective filtration gateway that separates molecules with a size difference as low as 0.2 newton-metre. The researchers show that the arrangement, orientation and alignment of these small cavities could be realized by selectively functionalized macrocycle molecules, in which the upper rim with highly reactive groups preferentially faces upright during the crosslinking reaction. The orientated architecture of macrocycles in nanomembranes could be verified by grazing incidence wide angle X-ray scattering (GI-WAXS). This allows for the first time to visualize the sub-nanometer macrocycle pores under high-resolution atomic force microscopy in ultrahigh vacuum, proving the concept of exploiting different nanopore sizes using different cyclodextrin identities with Angstrom precision.

As a functional proof of concept, these nanomembranes are applied to high-value pharmaceutical separations for enriching cannabidiol (CBD) oil, exhibiting higher ethanol permeance and molecular selectivity than commercial state-of-the-art membranes. This novel concept offers feasible strategies to orientate porous materials into nanopores in membranes that can provide accurate, fast and energy-efficient molecular separations.

Dr Zhiwei Jiang, now an EPSRC Future Leadership Fellow at Exactmer Ltd UK, said: “The demand for CBD derived pharmaceuticals has grown rapidly, due to their great efficacy in treating depression, anxiety, and cancer. Current state-of-the-art techniques for separating CBD molecules from extracts are expensive and energy intensive. Membranes can offer a cost-effective and energy-efficient alternative, but requires accurate separations between CBD and other natural components of similar dimensions dissolved in the extract solvent. Therefore, precise control of membrane pore size is critical to this opportunity. In our work, the pore size of the aligned macrocycle membranes can be precisely tuned at Angstrom precision, which enabled one order of magnitude higher solvent transport and three-fold higher enrichment of CBD than commercial benchmark membranes. This extends the great potential of applying membranes in high-value industries that require accurate molecular selectivity.”

Making membrane pores visible

At Bielefeld University, along with Dario Anselmetti, doctoral student Niklas Biere contributed to the study. Biere works with atomic force microscopy.

In his thesis, he developed the sophisticated technique that can visualize the nature of the tiny filter pores under ultra-high vacuum conditions and at low temperatures (minus 200 degrees Celsius). ‘This allowed us to enable our colleagues from London to see their membranes in detail, and we were able to confirm that they really do look as suspected,’ says Biere.

When using this method, the molecular surface of the nanomembrane is scanned with an ultrafine and ‘atomically sharp’ tip of a force sensor. It scans the surface and overwrites the molecular nature of the membrane into a relief. The image, which was created in the Bielefeld lab’s computer, was able to prove that the membrane has an extremely narrow pore size distribution that differs depending on the cyclodextrin starting molecule used.

The novel filter membrane is already available in DIN A4 format—an industrial upscaling can therefore be easily realized. And there are numerous possibilities for practical application: Thanks to nanomembrane technology, such filtration can perhaps be implemented manually or with a simple solar heat system,’ says Dario Anselmetti. For Niklas Biere, the specialized filter layer offers additional applications in medicine and pharmaceuticals: ‘For example, in blood tests, dialysis or the production of drugs.’