Loops for micro-organisms

Researchers develops a method of cultivating microbial communities in a permanently stable manner

The capabilities of complex microbial communities are used for numerous biotechnological processes. This requires special compositions of the microbial communities. However, these are often unstable and susceptible to disruption. UFZ researchers have now developed a "mass transfer method with a loop" that can stabilise microbial communities in the long term. Their study was recently published in PNAS.

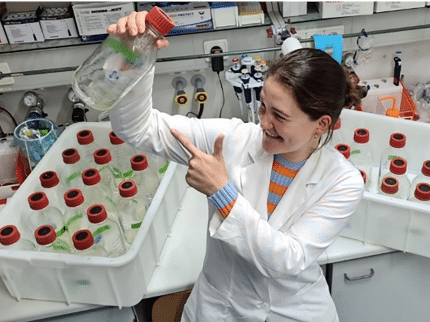

Loop reactor system: The five reactors with microbial communities were operated in the same way. The sixth reactor was connected to all five reactors. It synchronised the microbial communities and fed slow-growing bacteria back into the reactors.

© Zishu Liu / UFZ

On water, on land, and in the air - microorganisms are almost everywhere and are essential for all biogeochemical cycles on the planet. They are masters of degradation and transformation in water, soil - and even our intestines. Whether in waste water treatment plants or industrial biotechnological processes (e.g. for the production of food, biogas, or bio-based plastics), we harness the productivity of complex microbial communities. The right conditions ensure that the microorganisms can carry out their respective functions. However, stable processes also require a stable composition of the microbial community. "And that is precisely the challenge", says Prof. Susann Müller, who heads the Flow Cytometry working group at the UFZ Department of Environmental Microbiology. "The problem with microbial communities is that they can suddenly develop in completely different directions - even under the same conditions".

A minor random event can give rise to a completely different microbial community. And this can happen rather quickly when microorganisms grow exponentially. In addition, there is constant flow or mass transfer in bioreactors, which can be disastrous for some microorganisms. "In microbial communities, there are also microorganisms that are present only in comparatively small numbers and which multiply slowly", says Müller. "For example, the methane-forming microorganisms used in biogas production are indispensable for the desired processes. They have slower growth rates and come into play only at later stages. If the crucial microorganisms are inadvertently lost from the system, everything ultimately comes to a standstill". In order to prevent this, the UFZ research team has proposed a new method called "mass transfer with a loop" in a study recently published in the Proceedings of the National Academy of Sciences (PNAS). A kind of loop is built into the bioreactor system in order to stabilise the microbial community and prevent microbial groups from being lost from the system altogether. But how does it work? And how did the scientists go about it?

They first created five bioreactors, each with identical microbial communities. They then investigated whether and to what extent the composition of these communities changed over time. To do this, they used high-throughput flow cytometry to quickly examine single cells and characterise them in detail. Various parameters of the bacteria such as cell size, cell density, and DNA content can be determined. A sample with 200,000 bacterial cells can thus be displayed as precisely as a fingerprint - somewhat like a QR code - within just a few minutes. Using special computer methods, the research team analysed the huge amounts of data generated and was thus able to detect changes in the microbial composition. "As suspected, the microbial communities in the five bioreactors developed quite differently despite the identical conditions", says Müller. Next, the researchers introduced a loop into the system. This sixth bioreactor was connected to each of the five reactors via inflow and outflow. As a result, a constant exchange or mass transfer took place between the bioreactors. "Our investigations showed that the microbial communities in the bioreactors were synchronised with each other by the loop and that their composition and functions were permanently stabilised", says Müller. "In addition, the survival probability of micro-organisms with a low growth rate was considerably increased. This rescue effect can be crucial for many biotechnological processes".

The effects of mass transfers are not new; they are known, among other things, from sewage treatment plants in which part of the settling sludge from the third treatment stage is transferred back to the second treatment stage. "The principle was actually fairly obvious", says Müller. "But, so far, no one had investigated this in depth. In our study, we designed a completely new reactor system and combined a wide range of disciplines such as microbiology, ecology, biotechnology, single cell analytics, data science, and modelling. We were thus able to show for the first time that the principle of mass transfer with a loop can stabilise microbial communities in the long term. We hope that with our study we can provide stimuli for practical application".

Original publication

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Cell Analysis

Cell analyse advanced method allows us to explore and understand cells in their many facets. From single cell analysis to flow cytometry and imaging technology, cell analysis provides us with valuable insights into the structure, function and interaction of cells. Whether in medicine, biological research or pharmacology, cell analysis is revolutionizing our understanding of disease, development and treatment options.

Topic World Cell Analysis

Cell analyse advanced method allows us to explore and understand cells in their many facets. From single cell analysis to flow cytometry and imaging technology, cell analysis provides us with valuable insights into the structure, function and interaction of cells. Whether in medicine, biological research or pharmacology, cell analysis is revolutionizing our understanding of disease, development and treatment options.