Sustainable High Efficiency Hydrogenation Biocatalysis

Cleaner, safer and more efficient chemical manufacture

UK-based HydRegen are using a DrySyn OCTO reaction station from Asynt to help develop a next generation biocatalyst system that enables cleaner, safer, and more efficient chemical manufacture.

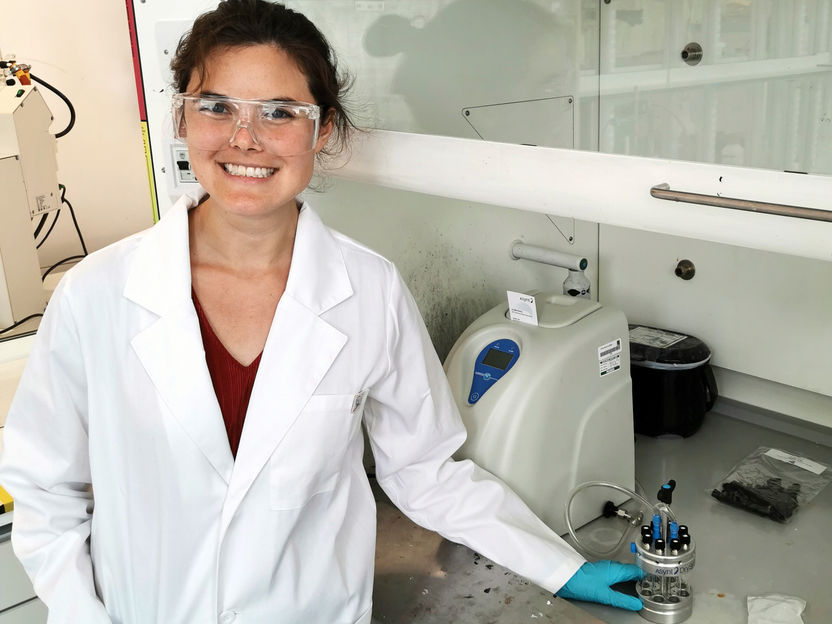

Dr Sarah Cleary with DrySyn OCTO / Hydrogen generator set-up at the HydRegen lab (Oxfordshire, UK).

Asynt Ltd

HydRegen spun-out from the Vincent Group in the Dept. of Chemistry at the University of Oxford in March 2021. They are developing novel and sustainable strategies for using the growing toolbox of NADH-dependent redox biocatalysts in chemical synthesis. Their system allows chemical manufacturing to harness the precision of biology with the efficiency of catalytic hydrogenation, allowing you to replace your heavy metal catalyst for highly selective hydrogenation reactions or decarbonise existing redox biocatalysis processes, all while operating within existing continuous flow hydrogenation reactors.

Dr Sarah Cleary, Chief Scientific Officer at HydRegen commented “We invested in a DrySyn OCTO because I had previously used the system and loved how it gave me the ability to simultaneously screen eight separate reaction variations under a controlled atmosphere, temperature, and means of agitation, thus advancing the process of biocatalyst development in a reproducible fashion. The DrySyn OCTO installed at HydRegen has been an incredibly useful tool for us. Because we’re using enzymes and don’t need pressurised hydrogen, the OCTO is perfect for screening catalysts and reaction parameters. It has definitely helped expedite our results and we are confident in those results thanks to the ability to carry out processes in triplicate under identical conditions in the OCTO.” Dr Cleary added “Because we didn’t want to use hydrogen cylinders in our lab, for various safety reasons, being able to hook up our DrySyn OCTO to a benchtop hydrogen generator also supplied by Asynt was very convenient. It’s been super simple to set up and to use and it’s small footprint means it doesn’t take too much valuable space in our fume hood!”.

Other news from the department business & finance

Get the life science industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Something is happening in the life science industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.