Coffee from lab?

Sustainable coffee grown in Finland

VTT has successfully produced coffee cells in a bioreactor through cellular agriculture. The innovation can help to make the production of coffee more sustainable. The first batches produced by VTT in a laboratory in Finland smell and taste like conventional coffee.

Elviira Kärkkäinen preparing coffee at VTT laboratory

VTT

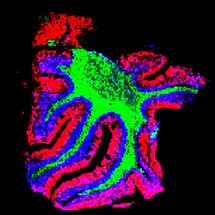

Coffee cell cultures (right) and roasted coffee produced by VTT's cellular agriculture method

VTT

With increasing demand and numerous sustainability challenges concerning traditional coffee agriculture, there is a pressing need for alternative ways of producing coffee. Due to the high demand of coffee, more acreage is required to produce enough coffee beans, leading to deforestation – particularly in sensitive rainforest areas.

VTT is developing coffee production through plant cells in its laboratory in Finland. In the process, cell cultures floating in bioreactors filled with nutrient medium are used to produce various animal- and plant-based products.

“At VTT, this project has been part of our overall endeavor to develop the biotechnological production of daily and familiar commodities that are conventionally produced by agriculture. For this, we use many different hosts, such as microbes, but also plant cells,” says Research Team Leader, Dr Heiko Rischer from VTT.

The work was started by initiating coffee cell cultures, establishing respective cell lines in the laboratory and transferring them to bioreactors to begin producing biomass. After analyses of the biomass, a roasting process was developed, and the new coffee was finally evaluated by VTT’s trained sensory panel.

The whole procedure required input from several disciplines and experts in the fields of plant biotechnology, chemistry, and food science.

“In terms of smell and taste, our trained sensory panel and analytical examination found the profile of the brew to bear similarity to ordinary coffee. However, coffee making is an art and involves iterative optimization under the supervision of specialists with dedicated equipment. Our work marks the basis for such work,” says Rischer.

Currently all coffee material produced in laboratory conditions represents experimental food and would require regulatory approval by the FDA to be marketed and sold to consumers in the United States. In Europe, the lab-grown coffee should first be approved as Novel Food before being marketed.

Technically the production process is based on existing and established technology such as conventional bioreactor operation. In fact, the idea that coffee cells could be used to make coffee was already presented in the 1970s by P.M. Townsley.

“The experience of drinking the very first cup was exciting. I estimate we are only four years away from ramping up production and having regulatory approval in place. Growing plant cells requires specific expertise when it is time to scale and optimize the process. Downstream processing and product formulation together with regulatory approval and market introduction are additional steps on the way to a commercial product. That said, we have now proved that lab-grown coffee can be a reality” says Rischer.

The project links to VTT’s strategic research targets to solve the world's biggest challenges. Cellular agriculture is one of the routes towards more sustainable food production.

“The true impact of this scientific work will happen through companies who are willing to re-think food ingredient production and start driving commercial applications. VTT collaborates and supports large enterprises and small companies in adopting opportunities in their product development. Ultimately, all efforts should result in more sustainable and healthy food for the benefit of the consumer and the planet,” concludes Rischer.