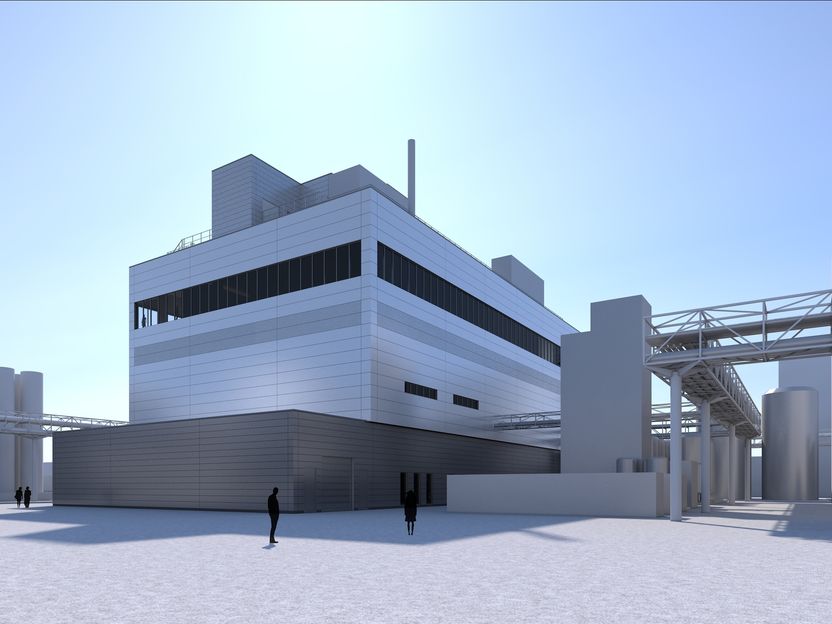

Merck Celebrates Topping-Out Ceremony for New Membrane Production Plant

Investment of more than € 140 million creates approximately 55 new jobs

Merck celebrated the topping-out ceremony for its new membrane production plant in Darmstadt, Germany. With the new facility, the company plans to expand manufacturing of Millipore Express® membranes, which are critical components in Millipore Express® filters and help ensure the sterility of biological drug products. The project with a volume of more than € 140 million is part of the € 1 billion investment in its global headquarters until 2025 that the company announced last year.

Merck

“As a science and technology company, we want to pave the way for new therapies and contribute to improving the lives of patients around the world. With this strategically important production facility for our Life Science business sector, we are investing in a future technology, enabling additional growth and creating new jobs at our company’s global headquarters,” said Stefan Oschmann, Chairman of the Executive Board and CEO of Merck.

Chris Ross, interim CEO of the Life Science business sector, added: “As a world-leading life science tools and solutions provider, we play a pivotal role in the growing biopharmaceutical membrane market. This investment increases our membrane manufacturing capacity and allows for more supply chain diversification. It also demonstrates our commitment to advancing the production of new therapies and our support for bringing important drugs to market.”

The new membrane production plant is expected to create approximately 55 new jobs. Construction began in March this year and is expected to be completed in 2022, followed by production process validation and commercialization. The new, four-story membrane plant will house immersion membrane casting equipment, quality control laboratories and offices.

Millipore Express® membranes from Merck will be manufactured at the new facility in Darmstadt, then processed into filters for pharmaceutical production at the company’s existing device Center of Excellence in Jaffrey, New Hampshire, USA.

Most read news

Other news from the department manufacturing

These products might interest you

Hahnemühle LifeScience Catalogue Industry & Laboratory by Hahnemühle

Wide variety of Filter Papers for all Laboratory and Industrial Applications

Filtration Solutions in the Life Sciences, Chemical and Pharmaceutical Sectors

Hydrosart® Ultrafilter by Sartorius

Efficient ultrafiltration for biotech and pharma

Maximum flow rates and minimum protein loss with Hydrosart® membranes

Hydrosart® Microfilter by Sartorius

Hydrophilic microfilters for bioprocesses

Minimal protein adsorption and high flow rates

Sartopore® Platinum by Sartorius

Efficient filtration with minimal protein adsorption

Reduces rinsing volume by 95 % and offers 1 m² filtration area per 10"

Polyethersulfone Ultrafilter by Sartorius

Reliable filtration with PESU membranes

Perfect for biotechnology and pharmaceuticals, withstands sterilisation and high temperatures

Polyethersulfone Microfilter by Sartorius

Biotechnological filtration made easy

Highly stable 0.1 µm PESU membranes for maximum efficiency

Sartobind® Rapid A by Sartorius

Efficient chromatography with disposable membranes

Increase productivity and reduce costs with fast cycle times

Get the life science industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.