For a climate-friendly industry: Using carbon dioxide and hydrogen as raw materials for sustainable chemicals

Evonik and Siemens Energy put pilot plant into operations

Evonik and Siemens Energy commissioned a pilot plant sponsored by the German Federal Ministry of Education and Research (BMBF) that uses carbon dioxide and water to produce chemicals. The necessary energy is supplied by electricity from renewable sources. The pilot plant is located in Marl, in the northern Ruhr area, and its innovative technology of artificial photosynthesis should contribute to the success of the energy revolution. It is an essential part of the Rheticus I and II research projects, which are sponsored by the Federal Ministry of Education and Research (BMBF) with a total of 6.3 million euros.

Commissioning of the Rheticus system, from left to right: Stefan Kaufmann, Innovation Officer "Green Hydrogen" of the Federal Ministry of Education and Research; Anja Karliczek, Federal Minister for Research ; Dr. Harald Schwager, Deputy Chairman of the Board of Management evonik Industries AG; Prof. Dr. Armin Schnettler, Executive Vice President New Energy Business, Siemens Energy

BMBF/Hans-Joachim Rickel

German Federal Minister of Education and Research Anja Karliczek said on the opening ceremony in Marl, "I am delighted that we have today given the go-ahead for a new test facility of the very highest standard in Marl.With Rheticus, we are showing how we can set up climate-friendly production processes in the chemical industry and at the same time manufacture new innovative products. And this works not only here in Germany, but potentially all over the world. This opens promising opportunities for technology exports. We want to promote effective climate protection and continue to have a strong industrial base in Germany. I am firmly convinced that we can succeed in both. I am pleased that my ministry is now investing a total of 6.3 million euros in the new pilot plant in Marl with this goal in mind and wish all those involved every success.“

Stefan Kaufmann, Member of the German Bundestag and Federal Commissioner for Green Hydrogen, states, "Today's start of the Rheticus pilot plant for the production of specialty chemicals is a real pioneering achievement. After all, a green hydrogen economy can only succeed in Germany as a country of innovation, if innovative technologies are used. This requires courage and a spirit of research. The project partners at Rheticus are exemplary in demonstrating this."

Harald Schwager, Deputy Chairman of the Executive Board of Evonik and responsible for innovations, said, "Climate protection is not possible without chemistry, because our industry supplies and develops solutions for the energy turnaround. Research projects such as Rheticus are a motivation and innovation driver for a sustainable society". At the same time, he warned against speed when phasing out fossil fuels. "Security of supply and reliability in political decisions set the framework in which new things are created.”

Christian Bruch, CEO of Siemens Energy: "Our goal is to use innovative technologies to enable new, more sustainable solutions. With our hydrogen and CO electrolysis, we are building a bridge from green electricity to sustainable material applications. The close cooperation between politics, science and business partners, like Evonik, is an important step in this direction.“ The Rheticus research project is a spin-off of the Copernicus projects, one of the largest research initiatives of the German Federal Government on energy system transformation. Rheticus demonstrates how the Power-to-X idea can be successfully put into practice.

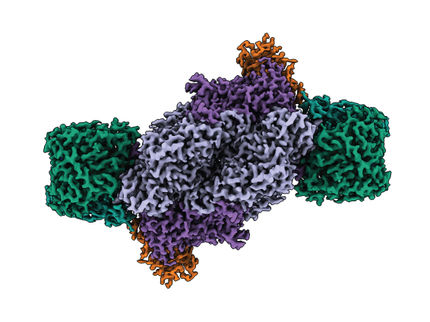

For the idea of artificial photosynthesis, which is behind the Rheticus experimental facility, the researchers took nature as a model. Just as plants use solar energy to produce sugar, for example, from carbon dioxide (CO2) and water in several steps, artificial photosynthesis uses renewable energies to produce valuable chemicals from CO2 and water through electrolysis with the help of bacteria. This type of artificial photosynthesis can serve as an energy store and thus help to close the carbon cycle and reduce carbon dioxide pollution in the atmosphere.

The pilot plant has started up in Marl, the largest Evonik site. It consists of a CO electrolyzer, developed by Siemens Energy, a water electrolyzer and the bioreactor with Evonik's know-how. In the electrolyzers, carbon dioxide and water are converted into carbon monoxide (CO) and hydrogen (H2) with electricity in a first step. This synthesis gas is used by special microorganisms to produce specialty chemicals, initially for research purposes. These are starting materials for special plastics or food supplements, for example.

In the coming weeks, the composition of the synthesis gas and the interaction between electrolysis and fermentation will be optimized. In addition, a unit for processing the liquid from the bioreactor will be set up to obtain the pure chemicals.

After successful completion of the current Rheticus project phase (Rheticus II), Evonik and Siemens Energy will have a unique platform technology at their disposal that can produce energy-rich and valuable substances such as specialty chemicals or artificial fuels from CO2 - in a modular and flexible manner.