Producing leather-like materials from fungi

Biofabrication includes upcycling of low-cost agricultural and forestry by-products

Leather is used as a durable and flexible material in many aspects of everyday life including furniture and clothing. Leather substitutes derived from fungi are considered to be an ethical and environmentally friendly alternative to traditional bovine leather. An international team led by material chemists Alexander Bismarck and Mitchell Jones from the University of Vienna demonstrate the considerable potential of these renewable sustainable fabrics derived from fungi in their latest review article in "Nature Sustainability".

They are CO2 neutral as well as biodegradable at the end of their life span.

© Alexander Bismarck

Traditional leather and its alternatives are typically obtained from animals and synthetic polymers. Leather can be considered a co-product of meat production with both livestock farming and the leather production process increasingly considered to be ethically questionable and environmentally unfriendly (e.g. deforestation for grazing, greenhouse gas emissions, use of hazardous substances in the tanning process). The production of synthetic leather materials from plastics such as polyvinyl chloride (PVC) or polyurethane (PU) also depend on chemicals derived from fossil fuels.

"This is where leather-like materials from fungi come into play, which, in general, are CO2 neutral as well as biodegradable at the end of their life span," says Alexander Bismarck from the Faculty of Chemistry at the University of Vienna, who additionally holds a visiting professorship at Imperial College London.

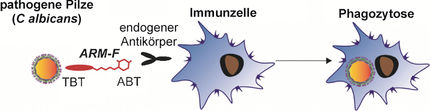

Growth of fungal mycelium

Leather substitutes can be produced from fungi by upcycling low-cost agricultural and forestry by-products (e.g. sawdust). These serve as a feedstock for the growth of fungal mycelium, which constitutes a mass of elongated tubular structures and represents the vegetative growth of filamentous fungi. Within a couple of weeks, the fungal biomass can be harvested and physically and chemically treated (e.g. pressing, cross-linking). "As a result, these sheets of fungal biomass look like leather and exhibit comparable material and tactile properties," says department head Alexander Bismarck. The first biotech companies are already marketing materials derived from fungi.

Leather substitute materials derived from fungi typically contain completely biodegradable chitin (which acts as a stabiliser in the material) and other polysaccharides such as glucans. In their own studies, Alexander Bismarck and Mitchell Jones (now affiliated with Vienna University of Technology) already conducted research using fungal species, such as the white button mushroom A. bisporus and bracket fungus D. confragosa, to produce paper and foam-like construction materials for applications, such as insulation.

Considerable potential as a leather substitute

In this review article, the scientists examine the sustainability of bovine and synthetic leathers and present an overview of the first developments and commercialisation of leather substitutes derived from fungi. According to the authors, one of the greatest challenges in the production of fungi-derived leather-like materials is still to achieve homogeneous and consistent mycelium mats, "exhibiting uniform growth and consistent thickness, colour and mechanical properties".

To date, the production of these materials has been driven mainly by entrepreneurial spirit. Fungi as a raw material for leather substitutes provide a cost-effective, socially and environmentally sound alternative to bovine and synthetic leather and are of particular interest to sustainability-conscious consumers and companies as well as to the vegan community, the researchers write. According to them, "substantial advances in this technology and the growing number of companies that are producing fungi-biomass-based leather alternatives suggests that this new material will play a considerable role in the future of ethically and environmentally responsible fabrics".