Incorporating biofunctionality into nanomaterials for medical, health devices

Advertisement

A team led by researchers from North Carolina State University has published a paper that describes the use of a technique called atomic layer deposition to incorporate "biological functionality" into complex nanomaterials, which could lead to a new generation of medical and environmental health applications. For example, the researchers show how the technology can be used to develop effective, low-cost water purification devices that could be used in developing countries.

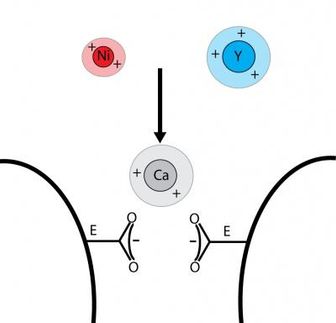

"Atomic layer deposition is a technique that can be used to create thin films for coating metals or ceramics, and is especially useful for coating complex nanoscale structures," says Dr. Roger Narayan, the paper's lead author. "This paper shows how atomic layer deposition can be used to create biologically functional materials, such as materials that have antibacterial properties. Another example would be a material that does not bond to proteins in the body, which could be used for implantable medical sensors." Narayan is a professor in the joint biomedical engineering department of NC State's College of Engineering and the University of North Carolina at Chapel Hill.

One of the applications discussed in the paper is a material that could be used as a filter for point-of-use water purification. "This would be very helpful in the developing world, or in disaster situations – like Haiti – where people do not have access to safe water," Narayan says. "Over one billion people do not have access to safe water. This can lead to a variety of public health problems, including cholera and hepatitis."

Specifically, the researchers show that atomic layer deposition can be used to create a film for coating nanoporous membranes, which may be used for filtering out pathogenic bacteria. "The film could also provide antimicrobial functionality," Narayan says, "to neutralize bacteria."

In the study, the researchers found that membranes treated with one of these films were able to neutralize two common pathogens: E. coli and Staphylococcus aureus . The researchers are currently working with colleagues to assess how well the membranes perform against a variety of environmental bacteria. It's anticipated that these membranes could find use in a variety of medical and environmental health applications, such as hemodialysis filters and implantable sensors.

Original publication: "Atomic layer deposition-based functionalization of materials for medical and environmental health applications."; Philosophical Transactions of the Royal Society A, 2010.