Genomes of biofuel yeasts reveal clues that could boost fuel ethanol production worldwide

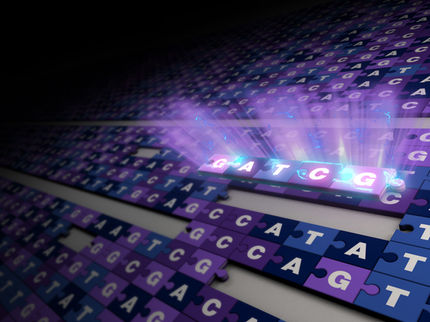

As global temperatures and energy costs continue to soar, renewable sources of energy will be key to a sustainable future. An attractive replacement for gasoline is biofuel, and in two studies published in Genome Research, scientists have analyzed the genome structures of bioethanol-producing microorganisms, uncovering genetic clues that will be critical in developing new technologies needed to implement production on a global scale.

Bioethanol is produced from the fermentation of plant material, such as sugar cane and corn, by the yeast Saccharomyces cerevisae, just as in the production of alcoholic beverages. However, yeast strains thriving in the harsh conditions of industrial fuel ethanol production are much more hardy than their beer brewing counterparts, and surprisingly little is known about how these yeast adapted to the industrial environment. If researchers can identify the genetic changes that underlie this adaptation, new yeast strains could be engineered to help shift bioethanol production into high gear across the globe.

Two studies published in Genome Research have taken a major step toward this goal, identifying genomic properties of industrial fuel yeasts that likely gave rise to more robust strains. In one of the studies, researcher Lucas Argueso and colleagues from Duke University and Brazil have sequenced and analyzed the structure of the entire genome of strain PE-2, a prominent industrial strain in Brazil. The group’s work revealed that portions of the genome are plastic compared to other yeast strains, specifically the peripheral regions of chromosomes, where they observed a number of sequence rearrangements.

Interestingly, these chromosomal rearrangements in PE-2 amplified genes involved in stress tolerance, which likely contributed to the adaptation of this strain to the industrial environment. As PE-2 is amenable to genetic engineering, the authors believe that their work on PE-2 will open the door to development of new technologies to boost bioethanol production.

In a second study published in Genome Research, researchers from Stanford University and Brazil led by Boris Stambuk and Gavin Sherlock have also analyzed the genome structure of industrial bioethanol yeasts, searching for variations in the number of gene copies in five strains employed in Brazil, including PE-2. Stambuk and colleagues found that all five industrial strains studied harbor amplifications of genes involved in the synthesis of vitamins B6 and B1 – compounds critical for efficient growth and utilization of sugar.

The group experimentally demonstrated that the gene amplifications confer robust growth in industrial conditions, indicating that these yeasts likely adapted to limited availability of vitamins in the industrial process to gain a competitive advantage. Furthermore, the authors suggest that this knowledge can be utilized to engineer new strains of yeast capable of even more efficient bioethanol production, from a wider range of agricultural stocks.

It is evident that an expanding human population will require more energy that exerts less impact on the environment, and the information gained from these genomic studies of industrial bioethanol yeasts will be invaluable as biofuel researchers optimize production and implement the technology worldwide.

Original publications: Argueso JL, Carazzolle MF, Mieczkowski PA, Duarte FM, Netto OVC, Missawa SK, Galzerani F, Costa GGL, Vidal RO, Noronha MF, Dominska M, Andrietta MGS, Andrietta SR, Cunha AF, LH Gomes, Tavares FCA, Alcarde AR, Dietrich FS, McCusker JH, Petes TD, Pereira GAG. "Genome structure of a Saccharomyces cerevisiae strain widely used in bioethanol production."; Genome Res 2009.

Stambuk BU, Dunn B, Alves Jr SL, Duval EH, Sherlock G.; "Industrial fuel ethanol yeasts contain adaptive copy number changes in genes involved in vitamin B1 and B6 biosynthesis."; Genome Res 2009.