VTT launches large European cooperation project for developing manufacturing method for biofuel

Raw-material for liquid biofuel from agricultural and forestry waste

VTT Technical Research Centre of Finland has started a large European project, combining the forces of European research institutes and companies for developing the next generation of biofuel. The NEMO project, which has received funding of EUR 5.9 million from the EU, is aimed at developing manufacturing methods for liquid biofuel from agricultural and forestry waste, such as straws and wood chips.

Agricultural and forestry waste is mainly lignocellulose, which consists of sugars but in a form that makes them difficult to be used by microbes in the production of ethanol. The project develops enzymes that can be used to cut lignocellulose into sugar compounds suitable for fermentation. The objective is also to tailor the metabolism of microbes so that they can produce large volumes of ethanol out of the biomass sugars economically and efficiently. The project evaluates the suitability of the developed enzymes and yeast strains for industrial biofuel manufacturing processes.

The NEMO project (Novel high performance enzymes and micro-organisms for conversion of lignocellulosic biomass to bioethanol) will last four years, and develops the next, 2nd generation production technology for the utilisation of lignocellulose raw material in the production of ethanol. The cost-effective production of the next generation biofuel requires the technology to be developed further.

Currently, nearly all biofuel is produced using the 1st generation technology, which is mainly based on the use of sucrose contained in sugarcane or starch-based glucose contained in corn as raw material. Apart from the sugarcane, the current production methods are not energy efficient enough and their impact on reducing carbon dioxide emissions is not sufficient.

The production of ethanol consists of four stages: the pre-processing of the raw material, the conversion of carbohydrates from polymers into sugar, the fermentation of sugar into ethanol using microbes and the distillation of ethanol. Different technologies are being globally developed for pre-processing the raw material. The NEMO project focuses on the pre-processing methods, hydrolysing cellulose using enzymes and the fermentation of the created sugars using tailored microbes.

According to the project coordinator Merja Penttilä, Research Professor at VTT, yeasts are excellent production organisms, suitable for large scale industrial production. Using enzymes, sugars can be released gently from the lignocellulose so that the sugar solution is not too toxic to microbes.

In the project, VTT focuses on the development of efficient enzymes and yeast production organisms.

Most read news

Topics

Organizations

Other news from the department science

Get the life science industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Urethral_cancer

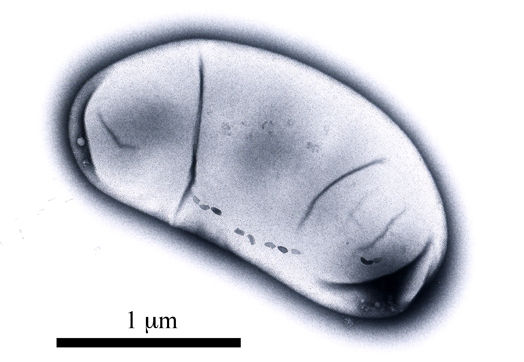

Magnetic microbe genome attracting attention for biotech research

Thyroid-stimulating_hormone

Fetal_trimethadione_syndrome

Fipamezole Transition from Biovail completed - Program Well Advanced Towards Phase III

Fitness_(biology)

How a molecular Superman protects the genome from damage - Scientists find a new role for RNAi protein Dicer in preventing collisions during DNA replication

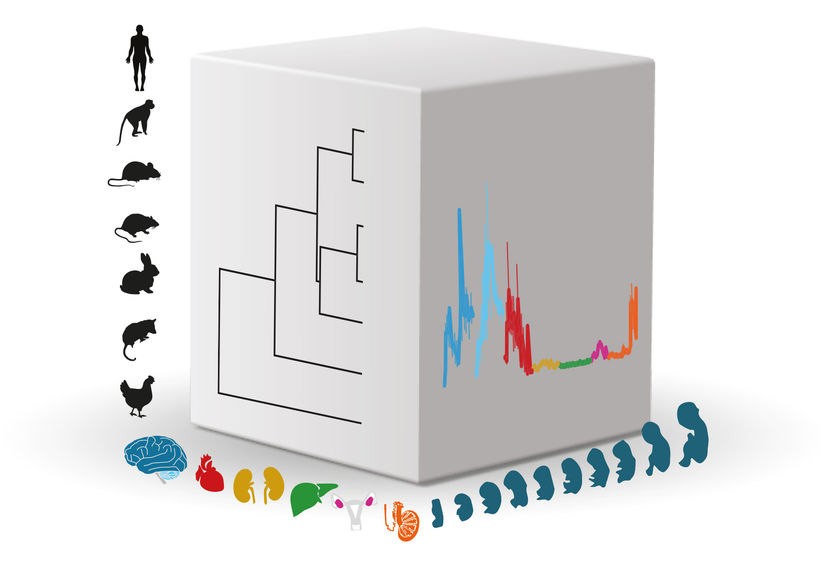

Networks of Gene Activity Control Organ Development

AIDS_advocacy

Evotec completes acquisition of Rigenerand