Implants that Respond to Your Body

Dynamic, 3D Pattern Formation within Protein-based Gels

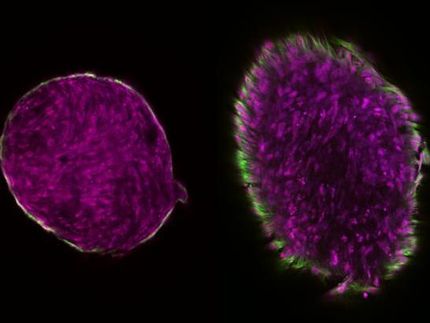

Modern regenerative medicine is on the lookout for implantable materials that can change as the surrounding tissue does, and two Stanford University researchers have made some new gel materials that do just that. Karin Straley and Professor Sarah Heilshorn have developed a method for preparing protein-based implant materials that can evolve with the changing needs of the host biological system. Not only can their new materials change in different ways at different times, they can do so at different places within the implant materials.

The materials, of a type known as hydrogels, are prepared from connected blocks of assorted designer proteins. Certain parts of some blocks degrade on exposure to specific enzymes, creating a three-dimensional pattern throughout the gel. If the gels are in a biological system and the triggering enzymes are selected to be ones produced by the system at a certain place and rate, the pattern evolves in response to the biochemistry of the system.

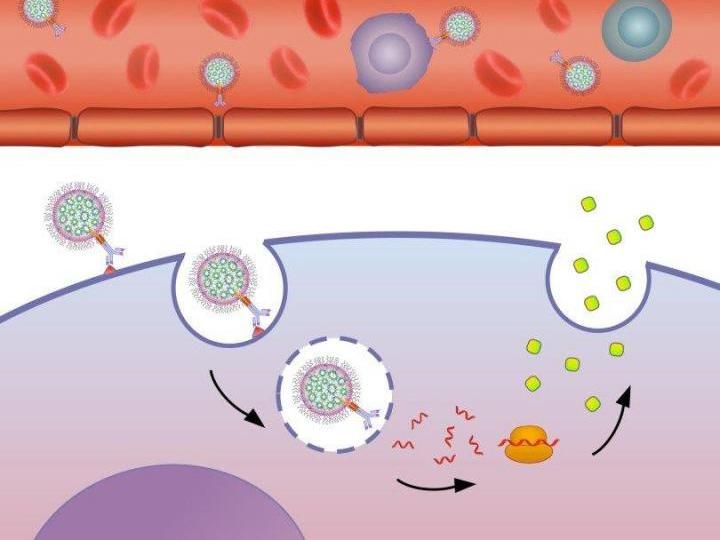

And, as a bonus for medical treatment, “we also demonstrated that the material released during this pattern formation can be modified to serve as a drug-delivery vehicle, enabling the release of multiple small molecules with distinct spatial and temporal delivery profiles,” states Prof. Heilshorn.

It seems the designer proteins were the key to the technological breakthrough. The proteins were prepared as block copolymers, which could then be crosslinked to form a hydrogel. Genetic templates were used to synthesize the protein-polymers, allowing precise, molecular level control over their content. This control enabled the Stanford researchers to develop hydrogels that were initially stable and subject to the usual gel mechanisms, and also to finely tune the degradation rates of selected components on exposure to the relevant proteases.

The new structures could contain completely internal voids or be open, connected geometries. Adding and removing material was no problem as both the protease enzymes that cause the degradation and the degraded material fragments diffuse readily through the hydrogel structure.

When asked to describe the possibilities presented by the work, Prof. Heilshorn explained: “As an application of this technology, a materials scientist can design a single medical implant to meet two or more separate sets of sequential, optimization criteria. For example, initially the implant should have mechanical properties that enable easy surgical implantation, such as a bulk slab of material that can be sutured into place without disturbing any delicate micro- or nanopatterns. Then after implantation, the locally secreted enzymes can remodel the material to create tunnels that may promote the growth of blood vessels into the implant [which then becomes a tissue scaffold]. Finally, the enzymes secreted by the blood vessels may trigger development of a porous 3D pattern to stimulate the infiltration of other cell types into the new tissue.

In the future, these scaffolds are envisioned as a means to enable “two-way” communication between cells and engineered biomaterials. For example, encapsulated stem cells will initially secrete a specific set of enzymes that could trigger the release of drugs to induce differentiation into a specialized cell type. These newly specialized cells will alter their secreted enzymes, turning off delivery of the differentiation drugs and turning on delivery of a new set of therapeutic drugs. Therefore, these biomaterials provide cells with a dynamic environment that can respond to fluctuations in cell and tissue biochemistry.”

Original publiction: K. S. Straley and S. C. Heilshorn; “Dynamic, Three-Dimensional Pattern Formation within Enzyme-Responsive Hydrogels”; Advanced Materials, 2009.

Most read news

Topics

Organizations

Related link

Other news from the department science

Get the life science industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Stanley_M._Gartler

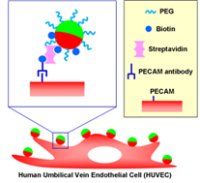

New platform based on biology and nanotechnology carries mRNA directly to target cells - Effective passage for therapies treating cancer and other diseases

Biotest starts combination therapy study with BT-062 in multiple myeloma

Arrhythmogenic_right_ventricular_dysplasia

Amplification_(psychology)

ChemMaps lets researchers navigate the chemical universe

American_Synesthesia_Association

Mary_Ainsworth

Category:Tetracyclic_antidepressants

-phob-

Cryo-force spectroscopy reveals the mechanical properties of DNA components